Hyprolapping

Microfinishing Services for the Highest Quality and Tightest Tolerance Markets

Precision and Quality

The most Dependable option for Quality precision grinding!

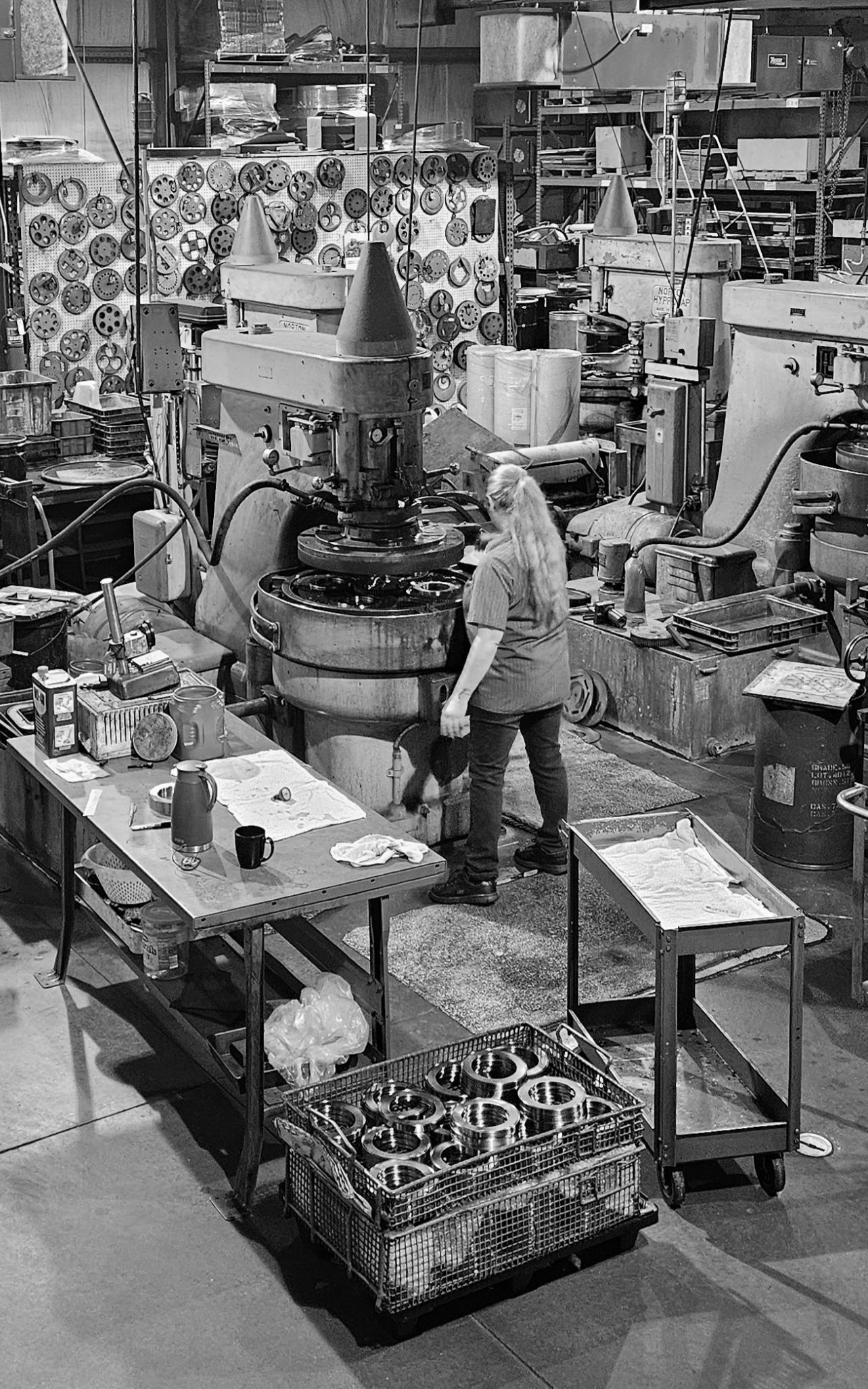

Hyprolapping allows two sides of a flat part to be ground simultaneously. Parts are inserted into fixtures or ”sprockets” which rotate in an orbital motion through the lapping wheels. Hyprolapping is capable of producing finishes measured in light bands. The lapping process is particularly useful for processing parts made from thin materials.

Capabilities and Details:

Capacity: 20″ Dia. w/ 2.5 max Radial Wall

Tolerances: to .0002

Flatness: Within .00005

Parallel: 0.0001

Finish: 2 RMS

Volume: 1 to 1,000,000 pcs.

Materials: Ferrous and Non-Ferrous,

including various Plastics

Single Side Operation Available

Advantages of Hyprolapping

Hyprolapping is a specialized precision machining process that draws from both honing and grinding. Here are just some of the primary benefits and key advantages of this advanced machining technique:

Precision Machining:

Hyprolapping offers exceptional precision, allowing for tight tolerances and fine surface finishes. Through this process, we’re able to provide customers with exceptional accuracy in dimensions and surface quality.

Better Surface Finishes:

Companies turn to us for this service because of our ability to provide extremely smooth surface finishes. With hyprolapping, we produce surfaces with low roughness – a result that limits the need for additional finishing processes.

Material Compatibility:

Part of the appeal of hyprolapping is that it’s ideal for diverse materials, including metals, ceramics, and some composites. This versatility makes it a preferred choice for manufacturers working with diverse materials.

Form and Roundness:

With our approach and equipment, we achieve outstanding results in both the form and roundness of machined parts. Hyprolapping corrects irregularities, which means each part will be the right shape.

Tight Tolerance Control:

Hyprolapping gives us notable control over tolerances, which means machined parts meet or exceed customers’ dimensional requirements.

Cost-Effective:

While maintaining high precision, Hyprolapping can be a cost-effective solution. Our streamlined process cuts down on required machining steps, which leads to lower overall production expenses.