COMMON WATER PROBLEMS AND

HOW TO SOLVE THEM!

View Our Guestbook

Sign Our Guestbook

Introduction to the problems and solutions for: Acidic Water, Bacteria,

Brackish, (Salty Taste) Carbon Dioxide or Carbonic Acid, Chlorine,

Chloride, Chemicals, Cryptosporidium, Hardness,

Iron, Rotten Egg odor in cold water, Rotten Egg odor in hot water only, Musty

Smell, Total Dissolved Solids, Oil or Gas, Salty, Sewage, Nitrates, Fluoride,

Sodium, Methane, Phenol, Lead, Total Dissolved Solids, Volatile Organics,

Manganese, pH, Silver, Sulfate, Zinc, Turbidity, Copper.

Complete Alphabetical List:

| Acidic Water |

Cryptosporidium |

pH |

| Aluminum |

Cyanide |

Potassium |

| Ammonia |

Fluoride |

Radium |

| Arsenic |

Giardia Lamblia |

Radon |

| Bacteria |

Hardness |

Selenium |

| Barium |

Hydrogen Sulfide (H2S) |

Silica |

| Benzene |

Iron |

Silver |

| Bicarbonate Alkalinity |

Lead |

SOC's |

| Borate (Boron) |

Legionella |

Sodium |

| Bromine (Bromide) |

Magnesium |

Strontium |

| Cadmium |

Manganese |

Sulfate |

| Calcium |

Mercury |

Taste |

| Carbon Dioxide (CO2) |

Methane |

Total Dissolved Solids

(TDS) |

| Carbon Tetrachloride |

Nickel |

THMs (Trihalomethanes) |

| Chloride |

Nitrate |

TOC (Total Organic Carbon) |

| Chlorine |

Nitrite |

Turbidity |

| Chromium |

Odor |

Uranium |

| Color |

Organics |

Viruses |

| Copper |

Pesticides |

VOCs (Volatile Organic

Chemicals) |

INTRODUCTION

Home water supplies contain dissolved minerals, gasses, bad smells,

and unsightly appearances that are easily removed. These problems can be

corrected by the use of Alpha Water Systems Inc treatment equipment. Common

water problems, their causes and our various products for treatment are

presented here.

Frequently there can be several methods to correct a given problem.

The selection of the type of equipment and treatment depends on the severity

of the problem.

It is not a good idea to install equipment on any water supply

without first taking a

water analysis

or water test. Correct sizing will provide maximum longevity of Alpha

Water Systems Inc. Equipment.

We suggest that you call or email with any question before purchasing

equipment so that one of our water treatment specialists can size your equipment

properly. This is done to assure you of the correct system for your water

conditions.

A 10 part $85.00 water test will give

us the information we need to size the correct equipment for your individual

needs. This analysis is for mineral content only.

Send a eight ounce water sample to our lab:

ALPHA WATER SYSTEMS INC.

P.O. BOX 1210

MONTAGUE, N.J. 07827

We offer a 3 part Hardness, Iron and pH test for Free, just mail

us a sample!

Please include your email address so we can contact you.

We have Home

Test Products available for testing your own water!

If bacteria or other contamination is suspected, send a water sample

to your Local or State

Board of Health. Please call us at 973-293-7856 If you have

any questions.

GLOSSARY OF COMMON TERMS USED IN WATER TREATMENT

Grains per Gallon (GPG) - A means of expressing the amount of dissolved

minerals in water. One grain per gallon equals 17.1 parts per million (ppm).

Parts Per Million - a common term used in water analysis. One part

per million (ppm) equals one pound per million pounds of water. Parts per

million may be converted to grains per gallon by dividing by 17.1. One part

per million is equal to one milligram per liter.

Compensated Hardness - Always used for determining water softener

capacity. It takes into account the amount of iron present in the water

as well as hardness content. To determine compensated hardness, add three

times the iron content in ppm to the actual hardness.

Example: Actual hardness = 45 grains per gallon, Iron content =

3 ppm (parts per million, same as mg/L, or milligrams per Liter). Twice the

iron content (2x3)=6 plus the actual hardness - 45 equals a compensated hardness

of 51 grains per gallon.

Ion - Electrically charged ions form when any mineral is dissolved

in water. (e.g. when common salt (NaCl) is dissolved in water it forms positively

charged ions (NA+) and negatively charged ions (CL-). The positively charged

ions are called cations and the negatively charged ions are anions.)

pH - This term is used to express the acidic or basic strength

of water. The pH scale ranges from 0 to 14. A pH of 7 is neutral indicating

a balance between acidic and basic elements. Values below 7 indicate increasing

acid strength as the pH approaches 0. Values above 7 indicate increasing

basic strength as the pH approaches 14.

COMMON WATER PROBLEMS AND THE PRODUCTS

TO SOLVE THEM

HARDNESS - EPA Maximum Contaminant level: N/A

Hardness is due to calcium and magnesium dissolved in water and

is measured in grains or ppm. Iron can also contribute to hardness.

These elements form scale in piping, water heaters, and dishwashers causing

expensive repairs. Hard water increases soap consumption, starches your laundry,

leave a scratchy feeling after bathing, leaves hair hard to manage, scales

glasses and dishes, and affects taste and tenderness of many cooked foods.

Hardness is removed with a Water Softener.

The proper size and type of softener depends on:

1. The compensated hardness (iron content determined)

2. The amount of water used per day (outside faucets excluded)

3. Flow rate required

IRON- EPA Maximum Contaminant level: 0.3 ppm

Iron in water imparts a bad metallic taste. It causes rust stains

in toilets, plumbing fixtures, tableware and laundry. As little as 0.1 ppm

of iron can cause these problems.

Iron can exist in water in one of two forms or both. Treatment

depends on the form of iron present. Waters containing "ferrous iron" are

clear and colorless when drawn. Exposure to air converts ferrous iron into

the the insoluble, reddish brown "ferric iron".

Iron can be removed from water by the following methods:

FERROUS IRON - Model AFE-10P

& Model AIFN-47,

AIFN-97 Terminater Iron Systems can handle up to 30 PPM.

A Water Softener

FGA SERIES can remove up to 5 ppm of ferrous iron depending upon size

and the type of softener.

FERRIC IRON - Model AFE-10P

Iron System If the water contains Hardness & considerable ferric

iron as evidenced by a reddish brown color, use a Model AFE-10P Iron

System as well as a sediment filter ahead of the Water Softener.

The sediment filter will remove a portion of the insoluble ferric iron

and the iron system with the water softener will remove the soluble ferrous

iron.Model AIFN-47

Terminater

Oxidizing iron filters (greensand filter) (Model AFE-10P)

Oxidizing filters can remove up to 10 ppm of both ferric (oxidized) and

ferrous (clear) iron. They work well with all types of private water system

pressure tanks. Sulphur removal is also possible with these filters when

levels are 2.0 ppm or less. In cases where both iron and sulphur are present

it is suggested that a sediment filter/water softener combination be installed

for removal of all iron. The sulphur can then be removed by an oxidizing

filter installed after the softener. Oxidizing filters require back washing

and regeneration with potassium permanganate. Automatic and manual types

are available. Do not use oxidizing filters on water supplies that have

a PH of 6.8 or less, sulphur in excess of 2.0 ppm or iron amounts exceeding

10 ppm. Call 973-293-7856 for

more information.

Catalytic type filters can remove up to 10 ppm of both ferric (oxidized)

and ferrous (clear iron) as well. The most popular catalytic iron

filter is the pyrolox media. Pyrolox works on the principle of a catalyst

reaction, but itself remains relatively unchanged. Pyrolox works on a principle

whereby the hydrogen sulfide, iron, and manganese are actually oxidized

in the media and simple back washing cleans the bed. No chemical regeneration

is required.

A micronizer and air vent is a good supplement to assist in any

oxidation process. A micronizer is installed ahead of some sort of water

storage tank (usually a pressure tank) and its purpose is to inject air into

the stream of water passing by. Once air is in the water it works to

solidify (oxidize) (Model

AIFN-47 Terminater) the iron in the water.

Chlorination

and Filtration

- this means of iron removal is recommended only when a sulfur or extreme

iron bacteria, or taste and odor problem also exists. Use a Chemical Solution Pump

and Tank to feed chlorine (household bleach) into the line ahead of

the pressure tank. Chlorine causes iron in the water to form particles which

can be filtered. On low pH waters an acid neutralizing compound should be

added to the chlorine solution to facilitate iron removal. Use an activated

carbon filter following the pressure tank to remove the iron particles as

well as any excess chlorine. NOTE - THE RETENTION TIME OF THIS METHOD

FOR IRON REMOVAL DEPENDS UPON AT LEAST 25 MINUTES OF CONTACT TIME FOR THE

CHLORINE TO FULLY REACT WITH THE IRON. THIS CONTACT TIME CAN BE PROVIDED

BY AN ADDITIONAL STORAGE TANK.

Acidic and Iron corrosion - Waters with a pH below 6.7 (acid waters)

usually will cause iron-pick up in piping systems and contribute to iron

staining problems. Blue to green staining will result if the piping is copper.

The lower the pH, the greater the corrosive tendency of the water. The

recommended pH limits of water for use in the home are 6.6 to 8.5 Waters

with pH less than 6.6 contain sufficient acidity to cause significant corrosion

and should always be treated. Waters containing appreciable amounts of

oxygen also tend to be corrosive. One common method of treatment to prevent

corrosion is:

1. Neutralization of acidity with an alkaline material.

Neutralization of Acid Waters - Acid neutralizing filters (Model AFN-10) contain

a mineral that reacts with acidity to raise the pH of water. This process

slowly dissolves the mineral and adds a few grains of hardness to the water.

The combination of an acid neutralizer filter and softener can be applied

to acidic waters containing up to 15 ppm of iron. Acid neutralizing filters

require the addition of several pounds of mineral once a year for a family

of 4-5.

NOTE: WATERS WITH PH BELOW 5.5 REQUIRE SPECIAL ATTENTION. SEND

A SAMPLE TO US FOR ANALYSIS AND RECOMMENDATION.

**What is pH and what's the

difference between acid and

base?

Water (H 2 O) contains both hydrogen (H+) ions and hydroxyl ions (OH-).

The term

pH is used to describe the measurement of the H+ ion concentration

of liquids and substances. Simply put, pH relates to the relative acidity

of a liquid solution. Each measurement is given a pH value on a scale of

0 to 14, with 7 being considered “neutral.”If a sample has more H+ ions than

OH- ions, it is considered acidic, or having a pH of less than 7. Examples

of acidic liquids around the house are vinegar, lemon juice and soft drinks

such as cola. If a sample has more OH- ions than H+ ions it is considered

basic or alkaline, and has a pH greater than 7. Liquids and substances that

are basic (alkaline) are baking soda, antacids and drain cleaners. For every

one unit of change on the pH scale—4 to 3, 7 to 8—there

is a tenfold change in how acidic or basic the sample is. For example,

the average pH of rain fall over much of the northeastern United States

is 4.3, or roughly 10 times more acidic than rainfall elsewhere in the United

States, which is 5.0-5.6. Lakes with a pH of 4 (acidic) are roughly 100

times more acidic than lakes with a pH of 6. Measuring the pH of water is

routine when assessing the “health” of a body of water. The pH of water

is usually always changing, and a change in the chemical nature of the system

will often reflect a change in the pH. The pH value

of water is important to most organisms, and a change in the pH can

result in the water becoming unsuitable. Most organisms are used to a specific

pH range, and can die from the effects of a change in the pH. At pH values

as low as 4.5 and as high as 9.6 the water becomes harmful to organisms

Model AFN-10

Chemical

Solution Pump - A chemical solution pump may be used to feed a solution

of acid neutralizer into the water system. The feed solution is prepared

by dissolving a rapidly soluble powder form of soda ash in water. Both the

strength of the feed solution and the chemical solution pump rate can be

adjusted to produce any desired pH. On private well systems, the chemical

solution pump is wired into the pressure switch so that it operates with the

well pump. In the absence of an electrically operated well or water pump (i.e.

city or gravity pressure supply) it would be best to use an acid neutralizing

filter. (AFN-10)

CHLORINE- EPA Maximum Contaminant level: N/A

Cholrine taste and odor in the water is usually caused by Chlorine's

deliberate introduction into municipal water supplies for the destruction

of bacteria and volatile organics. Chlorine can exist in water in its free

state (Called free chlorine) or can make chlorine compounds. Both are equally

objectionable.

The most cost effective method to remove chlorine from the water

is through a granular activated carbon filter. (Model AFC-10)

This non-maintenance solution eliminates the need to continually change

cartridge filters and the media lasts much longer than the cartridge counterparts.

Click here for

more information.

Carbon Filter Cartridges can also be used, but a whole house carbon

filter lasts longer and provides a better sediment filtration than a small

granular activated cartridge filter. If a reverse osmosis system is

used, use only a CTA membrane. TFC membranes have their limitation with

chlorine, unless they are pre filtered with a carbon block cartridge Click here for a Reverse

Osmosis unit.

MUSTY, MOLDY, OR WOODY SMELL - EPA Maximum Contaminant level: N/A

Caused by decay of organic matter or non-harmful bacteria. Use

a backwashable carbon filter AFC-10 to remove

the taste, odor, as well as sediment. In sever cases chlorination of the

well and piping system will be necessary.

A Reverse

Osmosis 26 GPD system would do well to purify the drinking water.

OIL OR GAS - EPA Maximum Contaminant level: Varied based on compound

Caused by natural elements in underground water or by leakage of

oil or gasoline storage tanks. Activated Carbon Filters

AFC-10 are very successful when the two are used in series.

If you have water that has absorbed petroleum products, please

send a sample to us, we can have it analyzed and prescribe proper treatment.

ROTTON EGG ODOR IN COLD WATER- EPA Maximum Contaminant level: N/A

Caused by hydrogen sulfide gas . This gas is very corrosive and

will react with iron to form a black sludge of iron sulfide.

Most sulfur waters contain from 1 to 5 ppm of hydrogen sulfide.

Use a Chemical

Feed Pump CT-015 to feed chlorine (bleach) in to the line ahead of

the pressure tank with Magnum Accelerator MAGEX (3 ppm

of chlorine is required for each ppm of hydrogen sulfide). Chlorine causes

the formation of sulfur particles that can be filtered. Install an Activated Carbon Filter

AFC-10 following the pressure tank to remove the sulfur particles as

well as any excess chlorine.

If it is your desire to have a low-maintenance solution, an AFE-10P (up to 4

ppm of hydrogen sulfide max) will solve your problem.

ROTTON EGG ODOR IN HOT WATER ONLY- EPA Maximum Contaminant level:

N/A

Since a magnesium *anode in the water heater creates a condition

favoring bacteria growth, remove the magnesium anode and replace it with

an aluminum rod. The manufacturer of your hot water heater can be called

to get the right size aluminum rod for the unit. When removing the old magnesium

anode rods be sure to not break off any small pieces of the old rod! Drain

and flush the water heater and chlorinate the water heater.

*The anode rod is installed by the manufacturer of the heater

to protect the heater against mineral corrosion and premature tank failure.

SALTY OR BRACKISH TASTE - EPA Maximum Contaminant level: 250

mg/L

Caused by high chloride or sulfate content. When the total of chlorides

exceeds 65 grains per gallon, the disagreeable taste will be noticed by

almost all people.

Filtering by Reverse Osmosis

is the best way to solve this problem.

SEWAGE - EPA Maximum Contaminant level: Varies on compound

The first thing to do if you suspect that your water is contaminated

by sewage is to send a water sample to your local, provincial, or national

governing body to determine if sewage pollution is present in your water

supply.

Eliminate the source of contamination if possible (Surface runoff,

cracked well casing, proximity to septic tank, faulty well seal, etc..). Next,

install either an Ultraviolet light with a small sediment pre filter with

little maintenance, only a light bulb change yearly! (UV MAX 14

GPM) or a much more involved Chemical Feed Pump

to feed chlorine (household bleach) into the system to a slight excess

(i.e. more than is required to react with the amount of contamination present).

This assures sufficient chlorine in the system to protect against small

fluctuations in the amount of contamination present. Install a drip valve

after the chlorinator and get a test kit to test chlorine content. Install

a backwashable carbon filter (AFC-10) to

remove excess chlorine and test for chlorine both before the block carbon

filter and after. The reduction of chlorine should be considerable.

Finally, a Reverse Osmosis

unit at the end of the process is recommended (CTA membrane for RO).

(Not needed with Ultraviolet light Model UV MAX)

NITRATES - EPA Maximum Contaminant level: 10 mg/L

Nitrates occur in water as a result of seepage through nitrate

bearing rocks or soils. The nitrate may also come from fertilizers or pollution

with organic wastes. Cyanosis ("blue baby") may occur in infants whose drinking

or formula water contains a high concentration of nitrates. Water containing

more than 10-20 ppm of nitrate expressed as nitrogen should not be used

for infant feeding. Nitrate is reduced to Nitrite in the body.

Nitrates can be removed from drinking water through Reverse Osmosis

Reductions of up to 96-100% are achieved.

Nitrates may also be removed throughout the whole house with a

Nitrate selective Water Conditioner. Model FGA-60N

Call 973-293-7856 for details.

FLUORIDES - EPA Maximum Contaminant level: 2 mg/L

Fluoride in water can be both good or bad, depending on the levels

of concentration. Research has shown that a concentration of about one milligram

per liter (mg/L or ppm) of fluoride in drinking water reduces tooth decay.

When drinking water contains excessive fluoride above two ppm,

it causes "endemic dental fluorsis". Sometimes called "Colorado Brown Stain",

it appears as a dark brown spotting of the teeth or causes them to become

chalky white. Above four milligrams of fluoride per liter can cause crippling

skeletal fluorosis, a serious bone disorder.

Reverse

Osmosis systems are effective at removing up to 96% of all Fluorides present

in water.

CARBON DIOXIDE OR CARBONIC ACID - EPA Maximum Contaminant level:

N/A

Rain water as it is falling through the sky absorbs Carbon Dioxide

to make Carbonic Acid. This acid when it comes into contact with limestone

absorbs the calcium from the limestone and this chemical reaction is where

hard water comes from. At times, the carbonic acid can't dissolve any substance

in the ground, remains acidic, and waits until it gets into a homeowner's

house before it begins to dissolve metal pipes and appliances. In certain

parts of the country where this problem is prevalent, it is serious.

The solutions are several, but probably the most effective is using

Model AFN-10

a 1 Cu Ft Acid neutralizer tank that backwashes to keep itself free of sediment.

This system requires periodic refills of Calcite.

Feeding a solution of soda ash sodium carbonate (NA2CO3) Is another

way to neutralize acidity. This second method requires a CT-015 Chemical Feed

Pump and Tank with bleed valve included.

SODIUM - EPA Maximum Contaminant level: N/A

High concentrations of sodium tend to increase the corrosive action

of water, give it unpleasant taste, and tend to hamper the operation of

ion exchange softeners in the removal of hardness.

Reverse Osmosis

will completely remove sodium from water.

METHANE - EPA Maximum Contaminant level: N/A

Wells that contain methane are generally located in areas where

gas and oil wells are common sights.

When water contains methane gas it is important to aerate it prior

to use for either industrial or household purposes.

PHENOL - EPA Maximum Contaminant level: N/A

An industrial waste. In concentrations as low as 1 part per billion,

this can cause an objectionable taste in chlorinated water due to the formation

of chlorophenols.

This may be removed by a Backwashable Model

AFC-10 Carbon Filter.

LEAD - EPA Maximum Contaminant level: 0.015 mg/L

At one time it was not generally known that Lead could be poisonous.

Unfortunately, this was a time when many of our cities were beginning to

provide underground plumbing to many neighborhoods. Lead was used as a soldering

agent to fix pipes together. Lead can be extremely dangerous to small children

and should be a priority to eliminate.

Certain Carbon Filters

are good lead deterrents as well as Reverse Osmosis

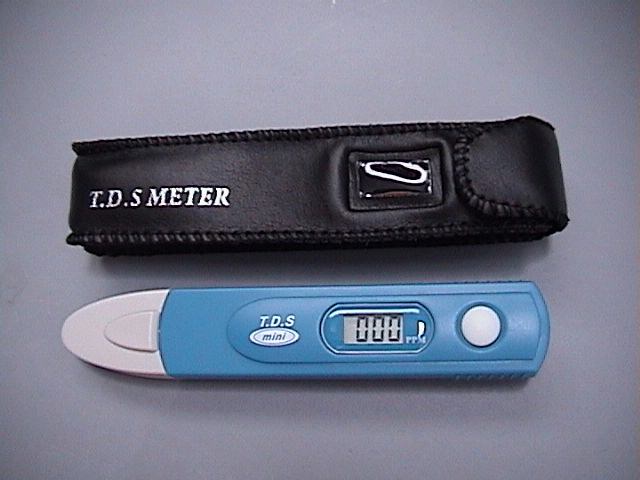

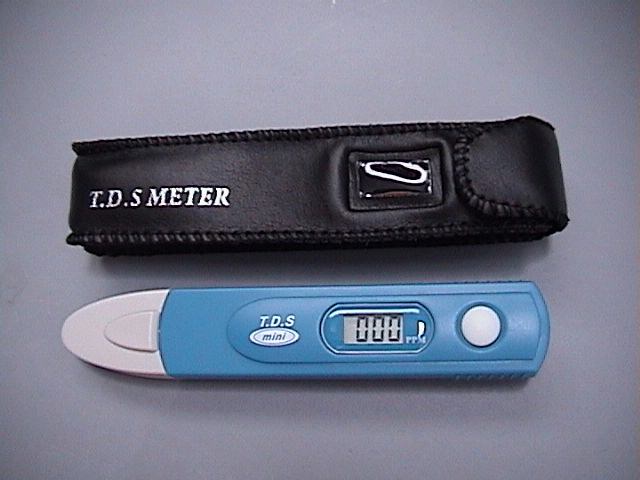

TOTAL DISSOLVED SOLIDS (TDS)- EPA Maximum Contaminant level: 500

mg/L

Pure water is a good conductor of electricity, true or false? The

answer might surprise you. Pure water is a very poor conductor of electricity,

in fact, it is highly resistant to electrical impulses. Its the other stuff

in the water that make it a good conductor of electricity, and the more stuff,

the better conductor of electricity water is. The primary ions that make

up TDS is Calcium Ca++, Magnesium Mg++, Sodium Na+, Iron Fe++, Manganese

Mn++, Bicarbonate HCO3-, Chloride Cl-, Sulfate SO4--, Nitrate NO3-, Carbonate

CO3--.

Reverse

Osmosis is the best way to eliminate these wide varieties of total

dissolved solids.We have a TDS chart below at the end of this page.

Test your own TDS and verify RO production.

Test your own TDS and verify RO production.

VOLATILE ORGANICS

Algae, Diatoms, Fungus, Molds, Bacteria, Viruses, Protozoa, Nematodes.

Disinfection methods include Reverse Osmosis,

or UV Light

Chemical disinfectants.

CHLORIDE - EPA Maximum Contaminant level: 250 mg/L

A natural forming mineral in sea water and sedimentary rock. The

main problems with chlorides have to do with taste, corrosion to pipes, and

chlorides is well known for being toxic to plants.

The best way to get rid of chlorides is through Desalination or Reverse Osmosis

FOAMING AGENTS - EPA Maximum Contaminant level: 0.5 mg/L

Detergents, fertilizer, pesticides, herbicides. At small levels,

mainly has a negative aesthetic effect.

Carbon Filtration

or Reverse Osmosis

MANGANESE - EPA Maximum Contaminant level: 0.05 mg/L

Naturally occurring metamorphic and sedimentary rocks, industrial

contaminant. Taste is affected. Staining, scaling, and discoloration of water.

Water

Softener or Manganese Greensand Filter Model AFE

pH - EPA Maximum Contaminant level: Less than 6.5, Greater than

8.5

6.5-8.5 is the acceptable range

Carbonates, bicarbonates, carbon dioxide, industrial contaminants.

If highly acidic (less than 6.5) it causes corrosion to pipes. If highly basic

(greater than 8.5) it causes staining.

Acid Neutralizer for pH lower than 6.6 (Model AFN-10)

SILVER - EPA Maximum Contaminant level: 0.1 mg/L

Natural mineral deposits, battery manufacturing, plating, medical

and pharmaceutical manufacturing. Causes discoloration of skin.

Ion

exchange, Reverse Osmosis

SULFATE - EPA Maximum Contaminant level: 250 mg/L

Naturally occurring, gypsum, mine and industrial wastes. Gives

off bad taste and has a laxative effects.

Ion

exchange, Reverse Osmosis

ZINC - EPA Maximum Contaminant level: 5 mg/L

Corrosion of plumbing materials, industrial contamination. Gives

off a foul taste.

Ion

exchange, Reverse Osmosis

TURBIDITY - EPA Maximum Contaminant level: 0.5 - 1.0 NTU

Turbidity is caused by erosion runoff and discharges. It mainly

has to do with measuring the light shining through a container holding water

in question. The less the light, the more the turbidity, the more the light,

the less the turbidity. Primarily, turbidity interferes with UV light or Chlorine disinfection.

For this reason it needs to be removed.

Turbidity can be removed by Filtration, Greensand, Reverse Osmosis

COPPER EPA Maximum Contaminant Level: 1.3 mg/L

Caused by corrosion of interior household and building pipes. Causes

stomach and intestinal distress. Wilson's disease.

Ion

exchange, Reverse Osmosis

ACIDIC WATER EPA Maximum

Contaminant Level: 6.5 pH

- Source - Acidic

waters usually get their acidity from the seepage of rain water, or acidic

industrial wastes.

-

- Treatment - Acidic

water can be neutralized by running it through a calcite filter (Model AFN-10), corosex

or a combination of the two. The calcite and the corosex both neutralize

by dissolving and they add hardness to the water as the neutralization takes

place; therefore, they both need to be replenished on a periodic basis.

- ALUMINUM

- Source - Aluminum

(Al+3) is an abundant metal in the Earth's surface, but its solubility in

water is so low that it is seldom a concern in municipal or industrial water

systems. The majority of natural water contains from 0.1 ppm up to 9.0

ppm of Aluminum, however the primary Source of Aluminum in drinking water

comes from the use of aluminum sulfate (alum) as a coagulant in water treatment

plants. The total dietary exposure to aluminum salts averages around 20

mg/day. Aluminum is on the US EPA's Secondary Drinking Water Standards list

with suggested levels of 0.05 - 0.2 mg/l.

-

- Treatment - Aluminum

can be removed from water by a Water Softener

cation exchanger but hydrochloric acid or sulfuric acid must be used for

regeneration to remove the aluminum from the resin. While this is suitable

for an industrial application it is not recommended for domestic use. Reverse Osmosis

will reduce the aluminum content of drinking water by 98 + %.

- AMMONIA

- Source - Ammonia

(NH3) gas, usually expressed as Nitrogen, is extremely soluble in water.

It is the natural product of decay of organic nitrogen compounds. Ammonia

finds its way into surface supplies from the runoff in agricultural areas

where it is applied as fertilizer. It can also find its way to underground

aquifers from animal feed lots. Ammonia is oxidized to nitrate by bacterial

action. A concentration of 0.1 to 1.0 ppm is typically found in most surface

water supplies, and is expressed as N. Ammonia is not usually found in well

water supplies because the bacteria in the soil converts it nitrates. The

concentration of Ammonia is not restricted by drinking water standards.

Since Ammonia is corrosive to copper alloys it is a concern in cooling systems

and in boiler feed.

-

- Treatment - Ammonia

can be destroyed chemically by Chlorination.

The initial reaction forms chloramine, and must be completely broken down

before there is a chlorine residual. Organic contaminants in the waste stream

will be destroyed by the chlorine before it will react with the ammonia.

- ARSENIC

- Source -

Arsenic (As) is not easily dissolved in water, therefore, if it is found

in a water supply, it usually comes from mining or metallurgical operations

or from runoff from agricultural areas where materials containing arsenic

were used as industrial poisons. Arsenic and phosphate easily substitute

for one another chemically, therefore commercial grade phosphate can have

some arsenic in it. Arsenic is highly toxic and has been classified by the

US EPA as a carcinogen. The current MCL for arsenic is 0.05 mg/l which was

derived from toxicity considerations rather than carcinogenicity.

-

- Treatment - If

in an inorganic form, arsenic can be removed or reduced by water treatment

processes. There are five ways to remove inorganic contaminants; Reverse Osmosis, Whole House Arsenic unit Ion Exchange, Activated Carbon,

and Distillation. Filtration through Activated Carbon

will reduce the amount of arsenic in drinking water from 40 - 70%. Anion

exchange can reduce it by 90 - 100%. Reverse Osmosis

has a 90% removal rate. If the arsenic is present in organic form,

it can be removed by oxidation of the organic material and subsequent coagulation.

-

- BACTERIA

- Source - Bacteria

are tiny organisms occurring naturally in water. Not all types of bacteria

are harmful. Many organisms found in water are of no health concern since

they do not cause disease. Biological contamination may be separated into

two groups: (1) pathogenic (disease causing) and

- (2) non-pathogenic (not

disease causing). Pathogenic bacteria cause illnesses such as typhoid fever,

dysentery, gastroenteritis, infectious hepatitis, and cholera. All water

supplies should be tested for biological content prior to use and consumption.

E.Coli (Escherichia Coli) is the coliform bacterial organism which is looked

for when testing the water. This organism is found in the intestines and

fecal matter of humans and animals. If E.Coli is found in a water supply

along with high nitrate and chloride levels, it usually indicates that waste

has contaminated the supply from a septic system or sewage dumping, and has

entered by way of runoff, a fractured well casing, or broken lines. If coliform

bacteria is present, it is an indication that disease causing bacteria may

also be present. Four or fewer colonies / 100 ml of coliforms, in the absence

of high nitrates and chlorides, implies that surface water is entering the

water system. If pathogenic bacteria is suspected, a sample of water should

be submitted to the Board of Health or US EPA for bacteriological testing

and recommendations. The most common non-pathogenic bacteria found in water,

is iron bacteria. Iron bacteria can be readily identified by the red, feathery

floc which forms overnight at the bottom of a sample bottle containing iron

and iron bacteria. It grows in the sample jar!

-

- Treatment - Bacteria

can be treated by Ultraviolet light,

Reverse

Osmosis or Chemical Oxidation and

Disinfection. Ultraviolet sterilization is the most efficient way

to kill bacteria. Ultraviolet sterilization needs to be pre filtered with

a 5 micron sediment filter and the water needs to be iron free. Chlorine Injection

is the oldest method of chemical oxidation and disinfection. Chlorine must

be fed at 3 to 5 ppm to treat for bacteria and a residual of 0.4 ppm of

free chlorine must be maintained for 30 minutes in order to meet US EPA

standards. Reverse Osmosis

as a back up to everything except the Ultraviolet Light, will remove

99+ % of the bacteria in a drinking water system.

-

-

- BARIUM

- Source - Barium

(Ba+2)is a naturally occurring alkaline earth metal found primarily in the

midwest. Traces of the element are found in surface and ground waters. It

can also be found in oil and gas drilling muds, waste from coal fired power

plants, jet fuels, and automotive paints. Barium is highly toxic when its

soluble salts are ingested. The current MCL for Barium is 2.0 mg/l.

-

- Treatment - Sodium

form cation exchange units (Water Softeners)

are very effective at removing Barium. Reverse Osmosis

is also extremely effective in its removal, as well as a Distiller.

-

- BENZENE

- Source - Benzene,

a byproduct of petroleum refining, is used as an intermediate in the production

of synthesized plastics, and is also an additive in gasoline. Gasoline

contains approximately 0.8 percent benzene by volume. Benzene is classified

as a volatile organic chemical (VOC) and is considered a carcinogen by the

US EPA. Benzene makes its way into water supplies from leaking fuel tanks,

industrial chemical waste, pharmaceutical industry waste, or from run off

of pesticides. The current US EPA MCL for Benzene is 0.005 mg/l.

-

- Treatment - Benzene

can be removed with Model AFC-10

Activated carbon. Approximately 1000 gallons of water containing 570

ppb of benzene can be treated with 0.35 lbs of activated carbon, in other

words; 94,300 gallons of water can be treated for every cubic foot of carbon.

The benzene must be in contact with the carbon for a minimum of 10 minutes.

If the required flow rate is 5 gpm, then 50 gallon of carbon is required;

which converts to approx. 7 cu. ft. The activated carbon must be replaced

when exhausted.

-

- BORATE (BORON)

- Source - Borate

B(OH)4- is a compound of Boron. Most of the world's boron is contained in

sea water. Sodium borate occurs in arid regions where inland seas once existed

but have long since evaporated. Boron is frequently present in fresh water

supplies in these same areas in the form of non-ionized boric acid. The

amount of boric acid is not limited by drinking water standards, but it can

be damaging to citrus crops if it is present in irrigation water and becomes

concentrated in the soil.

-

- Treatment - Boron

behaves like silica when it is in an aqueous solution. It can be removed

with an Anion Exchanger or adsorbed utilizing an Activated Carbon

Filter.

-

- BROMINE (BROMIDE)

- Source - Bromine

is found in sea water and exists as the bromide ion at a level of about 65

mg/l. Bromine has been used in swimming pools and cooling towers for disinfection,

however use in drinking water is not recommended. Ethylene bromide is used

as an anti-knock additive in gasoline, and methyl bromide is a soil fumigant.

Bromine is extremely reactive and corrosive, and will produce irritation

and burning to exposed tissues. Over 0.05 mg/l in fresh water may indicate

the presence of industrial wastes, possibly from the use of pesticides of

biocides containing bromine. Bromide is extensively used in the pharmaceutical

industry, and occurs normally in blood in the range of 1.5 to 50 mg/l.

-

- Treatment - Reverse Osmosis will

remove 93 -96 % of the bromide from drinking water. Since bromine is a

disinfectant, it along with the disinfection by-products can also be removed

with Activated

Carbon.

-

- CADMIUM

- Source - Cadmium

enters the environment through a variety of industrial operations, it is

an impurity found in zinc. By-products from mining, smelting, electroplating,

pigment, and plasticizer production can contain cadmium. Cadmium emissions

come from fossil fuel use. Cadmium makes its way into the water supplies

as a result of deterioration of galvanized plumbing, industrial waste or

fertilizer contamination.. The US EPA Primary Drinking Water Standards lists

Cadmium with a 0.005 mg/l MCL.

-

- Treatment - Cadmium

can be removed from drinking water with a sodium form cation exchanger

(softener). Reverse Osmosis

will remove 95 - 98 % of the cadmium in the water.

-

- CALCIUM

- Source - Calcium

is the major component of hardness in water and is usually in the range of

5 - 500 mg/l, as CaCO3 . Calcium is derived from nearly all rock, but the

greatest concentrations come from limestone and gypsum. Calcium ions are

the principal cations in most natural waters. Calcium reduction is required

in treating cooling tower makeup. Complete removal is required in metal

finishing, textile operations, and boiler feed applications.

-

- Treatment - Calcium,

as with all hardness, can be removed with a simple sodium form cation exchanger

(Water Softener).

Reverse

Osmosis will remove

- 95 - 98 % of the calcium

in the water.

-

- CARBON DIOXIDE

- Source - Free

carbon dioxide (CO2) exists in varying amounts in most natural water supplies.

Most well waters will contain less than 50 ppm. Carbon Dioxide in water

yields an acidic condition. Water (H2O) plus carbon dioxide (CO2) yields

carbonic acid (H2CO3). The dissociation of carbonic acid yields hydrogen

(H+) and bicarbonate alkalinity (HCO3). The pH value will drop as the concentration

of carbon dioxide increases, and conversely will increase as the bicarbonate

alkalinity content increases.

- H2O + CO2 <====>

H2CO3 <====> H+ + HCO3-

-

- Water with a pH of 3.5

or below generally, contains mineral acids such as sulfuric or hydrochloric

acid. Carbon Dioxide can exist in waters with pH values from 3.6 to 8.4,

but will never be present in waters having a pH of 8.5 or above. The pH value

is not a measurement of the amount of carbon dioxide in the water, but

rather the relationship of carbon dioxide and bicarbonate alkalinity.

-

- Treatment - Free

CO2 can be easily dissipated by aeration. A two column deionizer (consisting

of a hydrogen form strong acid cation and a hydroxide form strong base anion)

will also remove the carbon dioxide. The cation exchanger (Water Softener)

adds the hydrogen ion (H+) which shifts the above equation to the left

in favor of water and carbon dioxide release. The anion resin removes the

carbon dioxide by actually removing the bicarbonate ion. A forced draft

degasifier placed between the cation and anion will serve to blow off the

CO2 before it reaches the anion bed, thus reducing the capacity requirements

for the anion resin. The CO2 can be eliminated by raising the pH to 8.5

or above with a soda ash or caustic soda Chemical Feed System.

-

- CARBON TETRACHLORIDE

- Source - Carbon

tetrachloride (CCl4) is a volatile organic chemical (VOC), and is primarily

used in the manufacture of chlorofluoromethane but also in grain fumigants,

fire extinguishers, solvents, and cleaning agents. Many water supplies across

the country have been found to contain measurable amounts of VOC's. VOC's

pose a possible health risk because a number of them are probable or known

carcinogens. The detection of VOC's in a water supply indicates that a pollution

incident has occurred, because these chemicals are man-made. See Volatile

Organic Chemicals for a complete listing. The US EPA has classified carbon

tetrachloride as a probable human carcinogen and established an MCL of 0.005

mg/l.

-

- Treatment - Reverse Osmosis

will remove 70 to 80% of the VOC's in drinking water as will ultra filtration

and electrodialysis. Carbon tetrachloride as well as the other volatile

organic chemicals (VOC's) can also be removed from drinking water with activated

carbon filtration. The adsorption capacity of the carbon will vary with

each type of VOC. The carbon manufacturers can run computer projections

on many of these chemicals and give an estimate as to the amount of VOC

which can be removed before the carbon will need replacement.

-

- CHLORIDE

- Source- Chloride

(Cl-1) is one of the major anions found in water and are generally combined

with calcium, magnesium, or sodium. Since almost all chloride salts are

highly soluble in water, the chloride content ranges from 10 to 100 mg/l.

Sea water contains over 30,000 mg/l as NaCl. Chloride is associated with

the corrosion of piping because of the compounds formed with it; for example,

magnesium chloride can generate hydrochloric acid when heated. Corrosion

rates and the iron dissolved into the water from piping increases as the sodium

chloride content of the water is increased. The chloride ion is instrumental

in breaking down passivating films which protect ferrous metals and alloys

from corrosion, and is one of the main causes for the pitting corrosion of

stainless steel. The SMCL (suggested maximum contaminant level) for chloride

is 250 mg/l which is due strictly to the objectionable salty taste produced

in drinking water.

-

- Treatment - Reverse Osmosis

will remove 90 - 95% of the chlorides because of it's salt rejection capabilities.

Electrodialysis and distillation are two more processes which can be used

to reduce the chloride content of water. Strong base Anion Exchanger which

is the later portion of a two column deionizer does an excellent job at

removing chlorides for industrial applications.

-

-

- CHLORINE

- Source- Chlorine

is the most commonly used agent for the disinfection of water supplies. Chlorine

is a strong oxidizing agent capable of reacting with many impurities in

water including ammonia, proteins, amino acids, iron, and manganese. The amount

of chlorine required to react with these substances is called the chlorine

demand. Liquid chlorine is sodium hypo chlorite. Household liquid bleach

is 5-1/4% sodium hypo chlorite. Chlorine in the form of a solid is calcium

hypo chlorite. When chlorine is added to water, a variety of chloro-compounds

are formed. An example of this would be when ammonia is present, inorganic

compounds known as chloramines are produced. Chlorine also reacts with

residual organic material to produce potentially carcinogenic compounds,

the Trihalomethanes (THM's): chloroform, bromodichloromethane, bromoform,

and chlorodibromomethane. THM regulations has required that other oxidants

and disinfectants be considered in order to minimize THM formation. The

other chemical oxidants being examined are: potassium permanganate, hydrogen

peroxide, chloramines, chlorine dioxide, and ozone. No matter what form

of chlorine is added to water, hypo chlorite, hypochlorous acid, and molecular

chlorine will be formed. The reaction lowers the pH, thus making the water

more corrosive and aggressive to steel and copper pipe.

-

- Treatment - Chlorinated

water can be passed through a activated carbon filter. Activated carbon

model AFC-10

and up, Carbon Whole House Filter will remove 880,000 ppm of free chlorine

per cubic foot of media.

-

-

- CHROMIUM

- Source - Chromium

is found in drinking water as a result of industrial waste contamination.

The occurrence of excess chromium is relatively infrequent. Proper tests

must be run on the water supply to determine the form of the chromium present.

Trivalent chromium (Cr=3 ) is slightly soluble in water, and is considered

essential in man and animals for efficient lipid, glucose, and protein

metabolism. Hexavalent chromium

- (Cr=6 ) on the other

hand is considered toxic. The US EPA classifies chromium as a human carcinogen.

The current Drinking Water Standards MCL is .005 mg/l.

-

- Treatment - Reverse Osmosis

can effectively reduce both forms of chromium by 90 to 97%.

-

- COLOR

- Source - Color

in water is almost always due to organic material which is usually extracted

from decaying vegetation. Color is common in surface water supplies, while

it is virtually non-existent in spring water and deep wells. Color in water

may also be the result of natural metallic ions (iron and manganese). A

yellow tint to the water indicates that humic acids are present, referred

to as "tannins". A reddish color would indicate the presence of precipitated

iron. Stains on bathroom fixtures and on laundry are often associated with

color also. Reddish-brown is ferric hydroxide (iron) will precipitate when

the water is exposed to air. Dark brown to black stains are created by manganese.

Excess copper can create blue stains.

-

- Treatment - Color

is removed by Chemical Feed, retention and filtration. Activated Carbon

filtration will work most effectively to remove color in general. Anion

resin will remove tannins, but must be preceded by a softener or mixed

with fine mesh softener resin. See the headings Iron, Manganese, and Copper

for information their removal or reduction.

-

- COPPER

- Source - Copper

(Cu+3) in drinking water can be derived from rock weathering, however the

principal Sources are the corrosion of brass and copper piping and the addition

of copper salts when treating water supplies for algae control. Copper is

required by the body for proper nutrition. Insufficient amounts of copper

leads to iron deficiency. However, high doses of copper can cause liver

damage or anemia. The taste threshold for copper in drinking water is 2 -

5 mg/l. The US EPA has proposed a maximum contaminant level (MCL) of 1.3

mg/l for copper.

-

- Treatment - Copper

can be reduced or removed with sodium form strong acid cation resin (Special

Water

Softener) dependent on the concentration. If the cation resin is

regenerated with acid performance will be enhanced. Reverse Osmosis

or Activated Carbon Filtration will also remove copper by adsorption.

-

- CRYPTOSPORIDIUM

- Source - Cryptosporidium

is a protozoan parasite which exists as a round oocyst about 4 to 6 microns

in diameter. Oocysts pass through the stomach into the small intestine where

it's sporozoites invade the cell lining of the gastrointestinal tract. Symptoms

of infection include diarrhea, cramps, nausea, and low grade fever.

-

- Treatment - Ultraviolet light

is most effective and Filtration is also effective treatment for protozoan

cysts.

-

- CYANIDE

- Source - Cyanide

(CN-) is extremely toxic and is not commonly found at significant levels

in drinking water. Cyanide is normally found in waste water from metal finishing

operations. The US EPA has not classified cyanide as a carcinogen because

of inadequate data. No MCL level established or even proposed.

-

- Treatment - Reverse Osmosis

-

- FLUORIDE

- Source - Fluoride

(F+) is a common constituent of many minerals. Municipal water treatment

plants commonly add fluoride to the water for prevention of tooth decay,

and maintain a level of 1.5 - 2.5 mg/l. Concentrations above 5 mg/l are detrimental

to tooth structure. High concentrations are contained in waste water from

the manufacture of glass and steel, as well as from foundry operations.

Organic fluorine is present in vegetables, fruits, and nuts. Inorganic fluorine,

under the name of sodium fluoride, is a waste product of aluminum and is

used in some rat poisons. The MCL established for drinking water by the US

EPA is 4 mg/l.

-

- Treatment - Fluoride

can be reduced by anion exchange. Adsorption by calcium phosphate, magnesium

hydroxide or activated carbon will also reduce the fluoride content of drinking

water. Reverse

Osmosis will remove 93 - 95 % of the fluoride.

-

- GIARDIA LAMBLIA

- Source- Giardia

is a protozoan which can exist as a trophozoite, usually 9 to 21 mm long,

or as an ovoid cyst, approximately 10 mm long and 6 mm wide. Protozoans are

unicellular and colorless organisms that lack a cell wall. When Giardia are

ingested by humans, symptoms include diarrhea, fatigue, and cramps. The US

EPA has a treatment technique in effect for Giardia.

-

- Treatment - Slow

sand filtration or a diatomaceous earth filter can remove up to 99 % of the

cysts when proper pretreatment is utilized. Chemical oxidation - disinfection,

Ultraviolet Light, Nano filtration, and Reverse Osmosis

all effectively remove Giardia cysts. Ultraviolet Lights appears

to be very effective against the cysts when utilized in the chemical oxidation.Another

method is Chlorine, a widely used method of removing Giardia is mechanical

filtration. Because of the size of the parasite, it can easily be removed

with pre coat, solid block carbon, ceramic, pleated membrane, and spun

wrapped filter cartridges. For more information call 973-293-7856.

-

- HARDNESS

- Source - Hard

water is found over 80% of the United States. The hardness of a water supply

is determined by the content of calcium and magnesium salts. Calcium and

magnesium combine with bicarbonates, sulfates, chlorides, and nitrates to

form these salts. The standard domestic measurement for hardness is grains

per gallon (gpg) as CaCO3 . Water having

a hardness content less than 0.6 gpg is considered commercially soft. The

calcium and magnesium salts which form hardness are divided into two categories:

1) Temporary Hardness (containing carbonates), and 2) Permanent Hardness

(containing non-carbonates). Below find listings of the various combinations

of permanent and temporary hardness along with their chemical formula and

some information on each.

-

- Temporary Hardness Salts

- Calcium Carbonate (CaCO3) - Known as limestone, rare in water supplies.

Causes alkalinity in water.

- Calcium Bicarbonate [Ca(HCO3)2] - Forms

when water containing CO2 comes in contact with limestone. Also causes alkalinity

in water. When heated CO2 is released

and the calcium bicarbonate reverts back to calcium carbonate thus forming

scale.

- Magnesium Carbonate (MgCO3) - Known as magnesite with properties similar

to calcium carbonate.

- Magnesium Bicarbonate

[Mg(HCO3)2]

- Similar to calcium bicarbonate in its properties.

- Permanent Hardness Salts

- Calcium Sulfate (CaSO4) - Know as gypsum, used to make plaster of

paris. Will precipitate and form scale in boilers when concentrated.

- Calcium Chloride (CaCl2) - Reacts in boiler water to produce a low

pH as follows: CaCl2 + 2HOH ==> Ca(OH)2 + 2HCl

- Magnesium Sulfate (MgSO4) - Commonly known as epsom salts, may have

laxative effect if great enough quantity is in the water.

- Magnesium Chloride (MgCl2) - Similar in properties to calcium chloride.

- Sodium salts are also

found in household water supplies, but they are considered harmless as long

as they do not exist in large quantities. The US EPA currently has no national

policy with respect to the hardness or softness of public water supplies.

-

- Treatment - Water Softeners

can remove compensated hardness up to a practical limit of 120

gpg. If the hardness is above 30 gpg or the sodium to hardness ratio is

greater than 33%, then economy salt settings can not be used. If the hardness

is high, then the sodium will be high after softening, and may require that

Reverse

Osmosis be used for producing drinking water. For more information

call 973-293-7856

-

- HYDROGEN SULFIDE

- Source - Hydrogen

Sulfide (H2S) is a gas which imparts its

"rotten egg" SULFIDE odor to water supplies. Such waters are distasteful for

drinking purposes and processes in practically all industries. Most sulfur

waters contain from 1 to 5 ppm of hydrogen sulfide. Hydrogen sulfide can interfere

with readings obtained from water samples. It turns hardness and pH tests

gray, and makes iron tests inaccurate. Chlorine bleach should be added to

eliminate the H2S odor; then the hardness,

pH and iron tests can be done. Hydrogen sulfide can not be tested in a lab,

it must be done in the field. Hydrogen sulfide is corrosive to plumbing fixtures

even at low concentrations. H2S fumes will

blacken or darken painted surfaces, giving them a "smoked" appearance.

-

- Treatment - H2S requires Terminator Model AIFN,

the modern method of Sulphur Odor Systems. This is the easiest method that

requires no regular maintenance.

- For many years chlorine

has been used. The chlorine is to be fed in sufficient quantities to eliminate

it, while leaving a residual in the water (3 ppm of chlorine is required

for each ppm of hydrogen sulfide). Activated Carbon

AFC-10 filtration may then be installed to remove the excess chlorine.

For more information call 973-293-7856

-

-

- IRON

- Source - Iron

occurs naturally in ground waters in three forms, Ferrous Iron (clear water

iron), Ferric Iron (red water iron), and Heme Iron (organic iron). Each can

exist alone or in combination with the others. Ferrous iron, or clear water

iron as it is sometimes called, is ferrous bicarbonate. The water is clear

when drawn but when turns cloudy when it comes in contact with air. The

air oxidizes the ferrous iron and converts it to ferric iron. Ferric iron,

or ferric hydroxide, is visible in the water when drawn; hence the name

"red water iron". Heme iron is organically bound iron complexed with decomposed

vegetation. The organic materials complexed with the iron are called tannins

or lignins. These organics cause the water to have a weak tea or coffee color.

Certain types of bacteria use iron as an energy Source. They oxidize the

iron from its ferrous state to its ferric state and deposit it in the slimy

gelatinous material which surround them. These bacteria grow in stringy clumps

and are found in most iron bearing waters.

-

- Treatment - Ferrous

iron (clear water iron) can be removed with a Water Softener

provided it is less than 0.5 ppm for each grain of hardness and the pH

of the water is greater than 6.8. If the ferrous iron is more than 5.0

ppm, it must be converted to ferric iron by contact with a AFE-10P Iron

System oxidizing unit or agents such as chlorine, before it can be removed

by mechanical filtration. Ferric iron (red water iron) can simply be removed

by mechanical filtration. AIFN Series Terminator Iron

filters. Heme iron can be removed by an organic scavenger anion resin,

or by oxidation with chlorine followed by mechanical filtration. Oxidizing

agents such as chlorine will also kill iron bacteria if it is present. For

more information call 973-293-7856

-

- LEAD

- Source - Lead

(Pb+2) found in fresh water usually indicates contamination from metallurgical

wastes or from lead-containing industrial poisons. Lead in drinking water

is primarily from the corrosion of the lead solder used to put together

the copper piping. Lead in the body can cause serious damage to the brain,

kidneys, nervous system, and red blood cells. The US EPA considers lead to

be a highly toxic metal and a major health threat. The current level of lead

allowable in drinking water is 0.05 mg/l.

-

- Treatment - Lead

can be reduced considerably with a water softener. Activated carbon filtration

can also reduce lead to a certain extent. Reverse Osmosis

can remove 94 to 98 % of the lead in drinking water at the point-of-use.

-

- LEGIONELLA

- Source - In July

1976, there was an outbreak of pneumonia effecting 221 people attending

the annual Pennsylvania American Legion convention at the Bellvue-Stratford

Hotel in Philadelphia. Out of the 221 people infected, 34 died. It wasn't

until December 1977 that microbiologists were able to isolate a bacterium

from the autopsy of the lung tissue of one of the legionnaires. The bacterium

was named "Legionella pneumophila" (Legionella in honor of the American Legion,

and pneumophila which is Greek for "lung-loving") and was found to be completely

different from other bacteria. Unlike patients with other pneumonias, patients

with legionnaire's disease often have severe gastrointestinal symptoms,

including diarrhea, nausea, and vomiting. The US EPA has not set a MCL (maximum

contamination level) for Legionella, instead it has outlined the treatment

method which must be followed and the MCLG is 0 mg/l.

-

- Treatment - Chemical

oxidation-disinfection followed by retention, then filtration could be

used. Since Legionella is a bacteria, Reverse Osmosis

or Ultraviolet

Light are the preferred removal techniques.

-

- MAGNESIUM

- Source - Magnesium

(Mg+2) hardness is usually approximately 33% of the total hardness of a

particular water supply. Magnesium is found in many minerals, including

dolomite, magnesite, and many types of clay. It is in abundance in sea water

where its' concentration is five (5) times the amount of calcium. Magnesium

carbonate is seldom a major component of in scale. However, it must be removed

along with calcium where soft water is required for boiler make-up, or for

process applications.

-

- Treatment - Magnesium

may be reduced to less than 1 mg/l with the use of a Water Softener

or cation exchanger in hydrogen form. Also see "Hardness".

-

- MANGANESE

- Source - Manganese

(Mn+4, Mn+2) is present in many soils and sediments as well as in rocks

whose structures have been changed by heat and pressure. It is used in the

manufacture of steel to improve corrosion resistance and hardness. Manganese

is considered essential to plant and animal life and can be derived from

such foods as corn, spinach, and whole wheat products. It is known to be

important in building strong bones and may be beneficial to the cardiovascular

system. Manganese may be found in deep well waters at concentrations as

high as 2 - 3 mg/l. It is hard to treat because of the complexes it can

form which are dependent on the oxidation state, pH, bicarbonate-carbonate-OH

ratios, and the presence of other minerals, particularly iron. Concentrations

higher than 0.05 mg/l cause manganese deposits and staining of clothing

and plumbing fixtures. The stains are dark brown to black in nature. The

use of chlorine bleach in the laundry will cause the stains to set. The chemistry

of manganese in water is similar to that of iron. High levels of manganese

in the water produces an unpleasant odor and taste. Organic materials can

tie up manganese in the same manner as they do iron, therefore destruction

of the organic matter is a necessary part of manganese removal.

-

- Treatment - Removal

of manganese can be done by an Ion Exchange Water Softener

(sodium form cation - softener) or chemical oxidation - retention - filtration.

Removal with a water softener dictates that the pH be 6.8 or higher and

is beneficial to use countercurrent regeneration with brine make-up and

backwash utilizing soft water. It takes 1 ppm of oxygen to treat 1.5 ppm

of manganese. AFE-10P Greensand Filter with

potassium will remove up to 10 ppm if pH is above 8.0. Birm filter with

air injection will reduce manganese if pH is 8.0 to 8.5. Chemical feed (chlorine,

potassium permanganate, or hydrogen peroxide) followed by 20 minutes retention

and then filtered with AIFN-47 Terminator will remove

10 PPM , Greensand,

Carbon

will also remove the manganese.

-

- MERCURY

- Source - Mercury

(Hg) is one of the least abundant elements in the earth's crust. It exists

in two forms, an inorganic salt or an organic compound (methyl mercury). Mercury

detected in drinking water is of the inorganic type. Organic mercury inters

the food chain through fish and comes primarily from industrial chemical

manufacturing waste or from the leaching of coal ash. If inorganic mercury

inters the body, it usually settles in the kidneys. Whereas organic mercury

attacks the central nervous system. The MCL (maximum contamination level)

for mercury set by the US EPA is 0.002 mg/l.

-

- Treatment - Activated

carbon filtration is very effective for the removal of mercury. Reverse Osmosis

will remove 95-97 % of it.

- METHANE

- Source - Methane

(CH4), often called marsh gas, is the primary component of natural gas.

It is commonly found where land fills once existed and is generated from

decaying of plants or other carbon based matter. It can also be found in

and around oil fields. Methane is colorless, odorless, nearly invisible,

highly flammable, and often found in conjunction with other gases such as

hydrogen sulfide. Even though methane gas gives water a milky appearance

which makes it aesthetically unpleasant, there are no known health effects.

-

- Treatment - Aeration

or degasification is the only way to eliminate the problem of methane gas.

Venting the casing and/or the cap of the well will reduce the problem of

methane in the water, but may not completely eliminate it. Another method

is to provide an atmospheric holding tank where the methane laden water can

be vented to allow the gas to dissipate. This method may not be 100% effective

either. An aerator or degasifier is the proper piece of equipment to utilize

for the removal of methane. Water is introduced through the top, sometimes

through spray nozzles, and allowed to percolate through a packing material.

Air is forced in the opposite direction to the water flow. The water is

then collected in the bottom of the unit and repressurized. Call 973-293-7856

for more information on Methane gas removal.

-

- NICKEL

- Source - Nickel

(Ni+2) is common, and exists in approximately 85% of the water supplies,

and is usually around 1 ppb (part per billion). The US EPA has classified

nickel as a possible human carcinogen based on inhalation exposure. Nickel

has not been shown to be carcinogenic via oral exposure. No MCLG (maximum

contamination level goal) has been proposed.

-

- Treatment - Nickel

behaves the same as iron, and can be removed by a strong acid cation exchanger.

Activated carbon filtration can be used to reduce the amount of nickel in

drinking water, but may not remove it all. Reverse Osmosis

will remove 97 - 98 % of the nickel from drinking water.

- NITRATE

- Source - Nitrate

(NO3) comes into water supplies through the nitrogen cycle rather than via

dissolved minerals. It is one of the major ions in natural waters. Most

nitrate that occurs in drinking water is the result of contamination of

ground water supplies by septic systems, feed lots, and agricultural fertilizers.

Nitrate is reduced to nitrite in the body. The US EPA's MCL for nitrate is

10 mg/l.

-

- Treatment - Reverse Osmosis

will remove 92 - 95% of the nitrates and/or nitrites. Anion Exchange

Resin For whole house removal.

-

-

NITRITE

- Source - Nitrites

are not usually found in drinking water supplies at concentrations above

1 or 2 mg/l (ppm). Nitrates are reduced to nitrites in the saliva of the

mouth and upper GI tract. This occurs to a much greater degree in infants

than in adults, because of the higher alkaline conditions in their GI tract.

The nitrite then oxidizes hemoglobin in the blood stream to methemoglobin,

thus limiting the ability of the blood to carry oxygen throughout the body.

Anoxia (an insufficiency of oxygen) and death can occur. The US EPA has

established the MCL (maximum contaminant level) for nitrite at 1 mg/l.

-

- Treatment - Nitrites

are removed in the same manner as nitrates; Reverse Osmosis

or Anion

Exchange For whole house removal See Nitrate - Treatment.

-

- ODOR

- Source - Taste

and odor problems of many different types can be encountered in drinking

water. Troublesome compounds may result from biological growth or industrial

activities. The tastes and odors may be produced in the water supply, in

the water treatment plant from reactions with treatment chemicals, in the

distribution system, and/or in the plumbing of consumers. Tastes and odors

can be caused by mineral contaminants in the water, such as the "salty" taste

of water when chlorides are 500 mg/l or above, or the "rotten egg" odor

caused by hydrogen sulfide. Odor in the drinking water is usually caused

by blue-green algae. Moderate concentrations of algae in the water can cause

it to have a "grassy", "musty" or "spicy" odor. Large quantities can cause

the water to have a"rotten", "septic", "fishy" or "medicinal" odor. Decaying

vegetation is probably the most common cause for taste and odor in surface

water supplies. In treated water supplies chlorine can react with organics

and cause odor problems. Odor is listed in the Secondary Drinking Water Standards

by the US EPA. The contaminant effects are strictly aesthetic and a suggested

Threshold Odor Number (TON) of 3 is recommended.

-

- Treatment - Odor

can be removed by oxidation-reduction or by AFC-10 activated

carbon adsorption. Aeration can be utilized if the contaminant is in the

form of a gas, such as H2S (hydrogen sulfide). Chlorine is the most common

oxidant used in water treatment, but is only partially effective on taste

and odor. AFE-10P

Potassium Permanganate and oxygen are also only partially effective.

Chloramines are not at all effective for the treatment of taste and odor.

The most effective oxidizers for treating taste and odor, are chlorine

dioxide and ozone. Activated carbon has an excellent history of success

in treating taste and odor problems. The life of the carbon depends on the

presence of organics competing for sites and the concentration of the odor

causing compound.

-

- ORGANICS

- Source - Organic

matter makes up a significant part of the soil, therefore water soluble

organic compounds are present in all water supplies. Organic matter is reported

on a water analysis as carbon, as it is in the TOC (total organic carbon)

determination. The following is a list of organics which is regulated under

the Safe Drinking Water Act of 1986.

-

| Endrin |

1,1,2-Trichloroethane |

| Lindane |

2,3,7,8-Tetrachlorodibenzodioxin

(dioxin) |

| Methoxychlor |

Vydate |

| Toxaphene |

Simazine |

| 2,4-D |

Polynuclear hydrocarbons |

| 2,4,5-TP |

| Polychlorinated

biphenyls (PCB) |

|

| Aldicarb |

Phthalates |

| Chlordane |

Atrazine |

| Dalapon |

Acrylamide |

| Diquat |

Dibromochloropropane (DBCP) |

| Endothall |

1,2-Dichloropropane |

| Glyphosate |

Pentachlorophenol |

| Carbofuran |

Pichloram |

| Alachlor |

Dinoseb |

| Epichlorohydrin |

Ethylene dibromide (EDB) |

| Toluene |

Dibromomethane |

| Adipates |

Xylene |

| Hexachlorocyclopentadiene |

|

-

- Organics come from three

Major Sources:

- The breakdown of naturally

occurring organic materials.

- Domestic and commercial

chemical wastes.

- Chemical reactions that

occur during water treatment processes.

-

- The first Source is comprised of humic materials, microorganisms, and petroleum-based

aliphatic and aromatic hydrocarbons. The second source, derived from domestic and commercial chemical wastes include

wastewater discharges, agricultural runoff, urban runoff, and leaching from

contaminated soils. Organic contaminants comprising the third

source which are formed during water treatment include

chlorination and disinfection by-products such as THM's (Trihalomethanes),

or undesirable components of piping assembly such as joint adhesives.

-

- Treatment - Activated Carbon

is generally used to remove organics, color, and taste-and-odor causing

compounds. The contact time and service flow rate dictate the size of the

carbon filter. When removing organics, restrict flow rates to 2 gpm per

square foot of the filter bed. Reverse Osmosis

will remove 98 to 99% of the organics in the water. Anion Exchange

Resin retains organics, but periodically needs cleaning.

-

- PESTICIDES

- Source - Pesticides

are common synthetic organic chemicals (SOCs). Pesticides reach surface

and well water supplies from the runoff in agricultural areas where they

are used. Certain pesticides are banned by the government because of their

toxicity to humans or their adverse effect on the environment. Pesticides

usually decompose and break down as they perform their intended function.

Low levels of pesticides are found where complete break down does not occur.

There is no US EPA maximum contamination level (MCL) for pesticides as a

total, each substance is considered separately.

-

- Treatment - Activated

carbon filtration is an effective way to remove organics whether synthetic

(like pesticides) or natural. Ultra filtration will also remove

organic compounds. Reverse Osmosis

will remove 97 - 99% of the pesticides.

- PH

- Source - The term

"PH" is used to indicate acidity or alkalinity of a given solution. It is

not a measure of the quantity of acid or alkali, but rather a measure of

the relationship of the acid to the alkali. The PH value of a solution describes

its hydrogen-ion activity.

- The PH scale ranges between0

and 14.

-

- Acidic [ 0 ]=========[

7 ]==========[ 14 ] Alkaline

-

- Typically all natural

waters fall within the range of 6.0 to 8.0 PH. A value of 7.0 is considered

to be a neutral PH. Values below 7.0 are acidic and values above 7.0 are

alkaline. The PH value of water will decrease as the content of CO2 increases,

and will increase as the content of bicarbonate alkalinity increases. The

ratio of carbon dioxide and bicarbonate alkalinity (within the range of 3.6

to 8.4) is an indication of the PH value of the water. Water with a PH value

of 3.5 or below, generally contains mineral acids such as sulfuric or hydrochloric

acid.

-

- Treatment - The

PH can be raised by a neutralizing filter containing Calcite AFN- (Calcium

Carbonate - CaCO3 ) and/or Corosex (Magnesium Oxide - MgO) will combat

low pH problems. The peak flow rate of a neutralizing filter is 6 gpm /

sq. ft.

- POTASSIUM

- Source - Potassium

(K+) is an alkaline metal closely related to sodium. It is seldom that

one sees it analyzed separately on a water analysis. Potassium is not a

major component in public or industrial water supplies. Potassium is, however,

essential in a well balanced diet and can be found in fruits such as bananas.

-

- Treatment - Potassium

can be removed by a cation exchange resin, usually in the form of a softener.

It can also be reduced by 94 - 97% utilizing Reverse Osmosis.

For more information call 973-293-7856

-

- RADIUM

- Source - Radium

(Ra) is a radioactive chemical element which can be found in very small amounts

in pitchblende and other uranium minerals. It is used in the treatment of

cancer and some skin diseases. Radium 226 and radium 228 are of most concern

when found in drinking water because of the effects on the health of individuals.

Radium 228 causes bone sarcomas. Radium 226 induces carcinomas in the head.

Radioactivity in water can be naturally occurring or can be from man-made

contamination. Radiation is generally measured in curies (Ci). One curie

equals 3.7 x 1010 nuclear transformations per second. A picocurie (pCi) equals

10-12 curies. The US EPA has set the MCL (maximum contamination level) for

radium 226 and 228 at 5 pCi/L under the NIPDWR (national interim primary

drinking water regulations).

-

- Treatment - Radium

can be removed by sodium for Cation Exchange

Resin in the form of a water softener. Reverse Osmosis

will remove 95 - 98% of any radioactivity in the drinking water. For more

information call 973-293-7856

-

- RADON

- Source - Radon

(Rn) is a radioactive gaseous chemical element formed in the atomic disintegration

of radium. Radon 222 is one of the radionuclides of most concern when found

in drinking water. It is a naturally occurring isotope, but can also come

from man-made Sources. All radionuclides are considered carcinogens, but

the organs they target vary. Since radon 222 is a gas, it can be inhaled

during showers or while washing dishes. There is a direct relationship between

radon 222 and lung cancer.Under the NIPDWR (national interim primary drinking

water regulations), the MCL (maximum contamination level) for radon 222 is

set at 15 pCi/L (see radium for explanation of how radiation is measured).

-

- Treatment - Radon

is easily removed by aeration, since it is a gas. Carbon Filtration AFC-10

is also very effective in removing radon. For more information call 973-293-7856

-

- SELENIUM

- Source - Selenium

(Se) is essential for human nutrition, with the majority coming from food.

The concentration found in drinking water is usually low, and comes from

natural minerals. Selenium is also a by-product of copper mining / smelting.

It is used in photoelectric devises because it's electrical conductivity

varies with light. Naturally occurring selenium compounds have not been shown

to be carcinogenic in animals. However, acute toxicity caused by high selenium

intake has been observed in laboratory animals and in animals grazing in

areas where high selenium levels exist in the soil. The US EPA has established

the MCL for selenium at 0.05 mg/l.

-

- Treatment - Anion

exchange can reduce the amount of selenium in drinking water by 60 - 95%.

Reverse

Osmosis is excellent at reduction of selenium.

-

- SILICA

- Source - Silica

(SiO2) is an oxide of silicon, and is present in almost all minerals. It

is found in surface and well water in the range of 1 - 100 mg/l. Silica

is considered to be colloidal in nature because of the way it reacts with

adsorbents. A colloid is a gelatinous substance made up of non-diffusible

particles that remain suspended in a fluid medium. Silica is objectionable

in cooling tower makeup and boiler feedwater. Silica evaporates in a boiler

at high temperatures and then redeposits on the turbine blades. These deposits

must be periodically removed or damage to the turbine will occur. Silica

is not listed in the Primary or the Secondary Drinking Water Standards issued

by the US EPA.

-

- Treatment - Silica

can be removed by the anion exchange portion of the demineralization process.

Reverse

Osmosis will reject 85 - 90% of the silica content in the water.

For more information call 973-293-7856

-

- SILVER

- Source - Silver