I finally made a decision about what kind of propeller shaft support bracket to choose. The plans calls for the fin or P type but in my view these have some disadvantages. First, it is not made of composite but of steel, bronze or brass . This means a different material that sticks out of the hull with risk of leakage as it is a subject for high forces. To me it also looks quite vulnerable but it has to withstand ropes or netting that can be caught by the propeller but also a stone/rock on the wrong place when drying out.

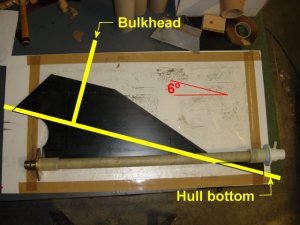

A more solid construction is possible with the reinforcement type shaft support, the skeg with build in stern tube. Advantage it is it can be made as a whole with the hull (all composite) but disadvantage is some more drag, more difficult to make and some extra facilities for the water lubrication. I think I can minimize the drag disadvantage by making the skeg as small and thin as possible with a carbon plate as base. The following picture shows the general idea.

Click in the picture for the photo gallery.

The engine page has been updated too and there you can find two photo’s of what can happen with a P- style shaft support bracket when catching a lobster pot rope.

Henny:

I used a PYI water cooled bearing and stuffing box on the inside and a green glass tube with a Cutless bearing on the outside all bonded tot he boat with a carbon skeg. Seemed very simple and worked well for ten years.Maybe you can not buy green tube there?

geoffrey

Green glass? Like epoxy / glass pipe? One can make your own, or do some shopping.

SR probably knows a source for these. (give him a call).

As for resistance: A wing shape has less resistance than a plate or a tube. You can still use the carbon plate, but shape it with epoxy and microballoons.

Best regards and Happy New Year,

Herman jr

Brands

Hi Geoffrey, I know, my first choice was a composite stern tube, but the accompanying bearings did not meet my quality demands. This brass stern tube is trapped between the two bearings and the fact it is glued to the surrounding glasfibres is just an extra. This type of bearing is so that they are easy to replace.

Hi Herman, the carbon plate is choosen for strength and to be able to make a thin trailing edge and the whole thing will be shaped with foam and microballoons.

Henny