Whether in the workshop, on the construction site or at home – with Festool Connected, we offer you intelligent products and smart apps that can optimally support you in every work situation.

Sliding compound mitre saw KAPEX KS 120 Set-UG 230V

Please check your cookie settings in order to use the comparison.

Go to the cookie settingsRecommended retail price of manufacturer. Prices of retailers may vary.↑

Functions

Quality down to the finest detail.

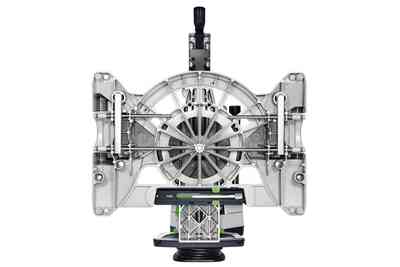

Guides left, guides right. Even where others only pretend to do so. With spherical bushings on both sides to offer a double layer of protection in terms of keeping the carriage precisely on course across extra-large columns. Double-sealed for an extremely long service life, always exact and with zero play.

- Twin-column guide with two bearings for unique precision

- Dual-line laser for an accurate indication of the cutting line

- Fine adjustment of the saw blade angle accurate to the millimetre from the front of the machine

- Special cutting position for cutting depths up to 120 mm

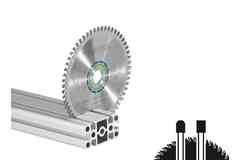

- FastFix saw blade changing for adaptation to the working material

- Twin-column guide for accurate cuts

- Precision angle transfer via bevel and dual-line laser

- Compact, lightweight design for convenient transportation

- Safety brake

Product details

Usage

Main applications

- Trimming skirting boards and cornices up to 120 mm in height – no calculations

- Cutting boards and panels up to 305 x 88 mm

- Trimming crown mouldings up to 168 mm in their original wall position

- Trimming square timber and beams up to 88 mm thick

Technical Data

-

Antistatic function

Mobile dust extractors and tools with the antistatic function to prevent static charge from accumulating when working.

-

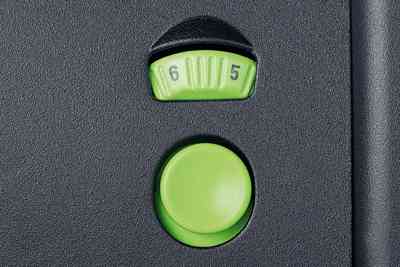

MMC digital electronics

Processor controlled “Multi Material Control” power electronics provide adjustable and constant speeds as well as temperature monitoring for work on all types of material.

-

FastFix

Makes changing routing, sawing, planing, sanding, drilling and screwdriving tools easier.

-

CLEANTEC

Integrated bayonet fitting as the connecting element between the extractor and the tool.

-

Quick-acting brake

For safe work when planing, sawing and routing.

-

Precision dual-line laser

Two laser lines for simple, precision positioning along the scribe mark from the left or right.

Downloads

Accessories

You can view 8 of 14 possible accessory items here. You can view 4 of 14 possible accessory items here.