H&P industries (Triad Group) FDA 483 1-7-2011

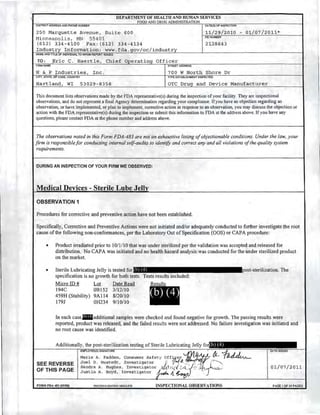

- 1. DEPARTMENT OF HEALTH AND HUMAN SERVICES FOOD AND DRUG ADMINISTRATION DISTRICT ADDRESS AND PHONE NUMBER DATE(S) OF INSPECTION 250 Marquette Avenue, Suite 600 11/29/2010 - 01/07/2011* FEI NUMBER Minneapolis, MN 5540 1 (612) 334-4100 Fax : (612) 334-4134 2128643 Industry Information: www.fda.gov/oc/industry NAME AND TITLE OF INDIVIDUAL TO WHOM REPORT ISSUED 1 TO: Eric C. Haertle, Chief Operating Officer FIRM NAME STREET ADDRESS IH & P Ind~stries, Inc . 700 W North Shore Dr CITY, STATE, ZIP CODE. COUNTRY TYPE ESTABUSHMEI<T INSPECTED Hartland, WI 53029 - 8358 OTC Drug and Device Manufacturer This document lists observations made by the FDA representative(s) during the inspection of your facility. They are inspectional observations, and do not represent a final Agency determination regarding your compliance. If you have an objection regarding an observation, or have implemented, or plan to implement, corrective action in response to an observation, you may disc uss the objection or action with the FDA representative(s) during the inspection or submit this information to FDA at the address above. If you have any I questions, please contact FDA at the phone number and address above. The observations noted in this Form FDA-483 are not an exhaustive listing ofobjectionable conditions. Under the law, your firm is responsible for conducting internal self-audits to identify and correct any and all violations ofthe quality system requirements. DURING AN INSPECTION OF YOUR FIRM WE OBSERVED: Medical Devices -Sterile Lube Jell I OBSERVATION 1 Procedures for corrective and preventive action have not been established. Specifically, Corrective and Preventive Actions were not initiated and/or adequately conducted to further investigate the root cause of !!he following non-conformances, per the Laboratory Out of Specification (OOS) or CAPA procedure: • Product irradiated prior to 10/1 /l O that was under sterilized per the validation was accepted and released for distribution. No CAPA was initiated and no health hazard analysis was conducted for the under sterilized product on the market. • Sterile Lubricating Jelly is tested for (h) (4) post-sterilization. The specification is no growth for both tests. Tests results included: Micro ID # Lot Date Read l94C OB1 52 3/12/ 10 459H (Stability) 9All4 8/20110 1791 OH234 911 Oil 0 In each case- additional samples were checked and found negative for growth. The passing results were reported, product was released, and the failed results were not addressed. No failure investigation was initiated and no roo t cause was identified. SEE REVERSE EMPLOYEE(S) SIGNATURE Marie A . Fadden, Cons umer Safety OffiJ:er Joel D. Huste dt, Investigator f! 'j't./IJ. ft. Additionally, the post-sterilization testing of Sterile Lubricating Jelly fo (b) (4) : . dL .... ' ... -.._ Di· TE ISSUED L,-')-T-~J <,;JJ.~-· OF THIS PAGE Sandra A . Hughe s , Inv es ti gator yJtJ J L Just in A. Boyd, Investigator t.i 11. Q ·. 0 1/07 / 2011 FORM FDA 483 (09/08) PREvlOUS EDITION OBSOLEl£ INSPECTIONAL OBSERVATIONS PAGE I Of 30 PAGES

- 2. DEPARTMENT OF HEALTH AND HUMAN SERVICES FOOD AND DRUG ADMfNISTRATION DISTRICT ADDRESS AND PHONE NUMBER DATE(S) OF INSPECTION 250 Marquette Avenue, Suite 600 11/29 / 2010 - 01/07/2011* FEl NUMBER Minneapolis, MN 55401 (612) 334-4100 Fax: (612) 334-4134 2128643 Industry Information: www.fda.gov/ oc/industry NAME AND TITLE OF INDIVIDUAL TO WHOM REPORT ISSUED TO: Eric C. Haertle , Chief Operating Officer FIRM NAME STREET ADDRESS 1 H & P Industries, Inc. 700 W North Shore Dr CITY, STATE. ZIP CODE. COUNTRY TYPE ESTABLISHMENT INSPECTED Hartland, WI 53029-8358 OTC Drug and Device Manufacturer • A stability sample of lubricating jelly lot 9H 169 failed its viscosity specification at th. month test point on 8/6/10 . An OOS Investigation OOS-1 0-061 was opened on 8/11110, but never completed. Th~month time point was tested and again failed the viscosity specification on II II 5110. The OOS investigation has not been completed and no root cause has been determined. • Follow-up to Complaint ID 13971 involved the testing of retains for lot 8D 153, product 07-8472 of lubricating jelly . The retain sample failed the viscosity specification on 10/ 14110. The complaint was closed and no OOS investigation into the failing results was implemented per SOP-QA-004. • CAP A H-1 0-00 I opened Jan 22, 20 I 0, has yet to address (b) (4) n pre-sterile lubricating jelly products. Procedure 01-013, revision B- Corrective and Preventive Action Procedure (CAPA) which states in section 5.6 "** OBSERVATION 2 A process whose results cannot be fully verified by subsequent inspection and test has not been validated according to established procedures. Sterile lubricating jelly is accepted and given a final QC/QA release upon r . II I l l I " . l . I " . • I I I I cess had never been validated prior to 6/14/10 and product was accepted with a (b) (4) for all packaging configurations. A validation for sterile lubricating jelly VAL-PQRPT -002 was completed an- - on 6/14/IO.~um dosage re11uired for the packaging configurations established during validation wa __!__~_ for packets,~or bottles, and l9JCJII for tubes. These new specifications were not updated with the contract sterilizer until!0/ 1/ 10. (b) (4) ' The validation was not completed adequately because: • There is no justification for (b) (4) EMPLOYEE(S) SIGNATURE DATE ISSUED M ari e A . Fadde n , Con s umer Safe t y Of fice r ~~ J o e l D. Hus t edt, Inves t i gator i!f._1 1. SEE REVERSE Sandra A. Hughes, Inve stig a tor 1 1 I 01 / 07 /2 011 OF THIS PAGE Jus t i n A. Boyd, I n ves t i gato r ~ FORM FDA 483 (09/08) PREVIOUS EDITION OBSOLETE _ _INSPECTIONAL OBSERVATIONS PAGE 2 OF JO PAG~

- 3. DEPARTMENT OF HEALTH AND HUMAN SERVICES FOOD AND DRUG ADM!N!STRAT!ON DISTRICT ADDRESS AND PHONE NUMBER DATE(S) OF INSPECTION 250 Marquette Avenue, Suite 600 11/29/2010 - 01 / 07 / 2011* FEI NUMBER Minneapolis, MN 55401 (612) 334-4100 Fax: (612) 334-4134 2128643 Industry Information: www.fda.gov/oc/industry NAME 'AND TITLE OF INDIVIDUAL TO WHOM REPORT ISSUED TO: Eric C. Haertle, Chief Operating Officer FIRM NAME STREET ADDRESS H & P Industries, Inc. 700 W North Shore Dr CITY. STATE . ZIP CODE. COUNTRY TYPE ESTABLISHMENT INSPECTED Hartland, WI 53029-8358 OTC Drug and Device Manufacturer (b) (4) detennined during the validation. • The bottMMduct family samples were not representative ofroutine manufacturing in that deviation H0310.014 allowed fmished lots to be manufactured from QB• production batch for the purpose ofhavingUIDJ finished lots to use in a validation. • The development of product families was not justified . • The collection ofbioburden samples was not documented and did not ensure samples are representative of the manufacturing process. • The bioburden recovered from product samples was not characterized . • There is no justification for the maximum (b) (4) • The final validation was signed for approval on 6/14/ 10, but it was not reviewed by the quality laboratory manager until6/18/10. OBSERVATION 3 Procedures to prevent contamination of equipment or product by substances that may have an adverse effect on product quality have not been adequately established. Specifically, potential sources of bioburden in the production area for lubricating jelly were observed on 12/ 1110: • Lubricating jelly mixing and holding tanks were left uncovered during mixing and filling operations. • Tank . had holes that were a potential route of contamination. The top of this tank appeared to have had a stagnant puddle near these holes that had since dried up. • Filling line DJID and DJID are used to fill the lubricating jelly packets. Rollers that contact the inner surface of the packaging were observed to have built-up dirt and dust. Filling nozzles were observed to be leaking with built up product on them. • Filling line[IIBI is used to fill the lubricating jelly tubes. The indicator on the sterile air filter shows the filter needed to be changed. EMPLOYEE(S) SIGNATURE DATE ISSUED M arie A . Fa dde n, Consume r Safety ~f ficer J~ SEE REVERSE J oel D. Hus t edt, I nvestigator J".l San d r a A. Hughes, Inves ti ga toAA~ 01 / 07 /2 011 OF THfS PAGE Jus t i n A. Boyd, Inv estigat o r O~ f()RM FDA 483 (09108) PREVlOUS EDITION OBSOLETE INSPECTIONAL OBSERVATIONS PAGEl OF 30 PAGES

- 4. DEPARTMENT OF HEALTH AND HUMAN SERVICES FOOD AND DRUG ADMINISTRATION DISTRICT ADDRESS AND PHONE NUMBER I, DATE(S) OF INSPECTION 250 Marquette Avenue, Suite 600 11/29 / 201 0 - 01/07 / 20 11 * Minne apo li s , MN 5 540 1 I, FEI NUMBER (612) 334 - 4100 Fax: (612) 334-4134 Industry Information: www.fda . gov/oc/industry I 2128643 NAME AND TITLE OF INDIVIDUAL TO WHOM REPORT ISSUED TO: Eric c. Haertle, Chief Ope r ating Office r FIRM NAME STREET ADDRESS H & p Industries, Inc . 700 w North Shore Dr CITY, STATE. ZIP CODE, COUNTRY TYPE ESTABLISHMENT INSPECTED I Hartland , WI 53029 ~ 8358 OTC Drug and Devi c e Manufacturer OBSERVATION 4 Procedures for monitoring and control of process parameters for a validated process have not been adequately established. Specifically, bioburden monitoring and quarterly dose audits (QDA) of the lubricating jelly product families are to be completed on a quarterly basis per SOP-LAB-005-00. I • The thir. farter bioburden monitoring for the packets had an average bioburden ofililiQlfu, excJ:Qjpt e action limit of cfu, and the tubes had an average bioburden ofa l cfu, exceeding the action limit o • cfu . A Quality Assurance Investigation was not initiated in either instance as described in SOP-LAB-005-00. • No bioburden monitoring or QDA has been done since the validation was approved 6114110 for the bottle product family. There were no bottles being manufactured when samples for the quarter three bioburden monitoring and dose audit were submitted in August of20 10. The firm manufactured bottles, lot OK20, that was opened 1011 3/10, but did not complete bioburden monitoring or a QDA for this lot. OBSERVATION 5 Procedures for finished device acceptance have not been established. Specifically, lot 01257 of Sterile Lubricating Jelly was accepted, distributed , and the l ot was closed on 11 / 11/10. However, ) there was no Post-sterilization Finished Goods Analysis conducted per Master Batch Formula and Mixing Instruction for specification 04-094. OBSERVATION 6 Procedures to ensure that all purchased or otherwise received product and servi~es con form to specified requirements have ·not been established . Specifically, • Specifications for the tubes used in manufacturing lubricating jelly state the tube must have a peelable foil seal. Incoming inspection of tubes is documented on FM- 10-89 17TB, but it does not include an inspection of the foil seals. No FM- 10-891 7- tubes used in the packaging of lot OF I43, product 10-89 17. Approved tube supplier • has never been audited per the procedure "Supplier Qualification and Management System" #SOP-QA-010-01 effective 10/28/ 10. Additionally, 6 complaints were received of tubes manufactured July 2010-August 2010 concerning faulty seals • EMPLOYEEIS) SIGNATURE DATE ISSUED Marie A. Fadden , Consumer Safet~ Office~~ SEE REVERSE Joel D. Hus t e dt, Investigator j7,~' Sandra A. Hughes, Invest i ga t or 01/07/20 11 OF THIS PAGE Justi n A. Boyd, Inves ti gator ~ FORM FDA 483 (09/08) PREVIOUS EDITION OBSOLETE INSPECTIONAL OBSERVATIONS PAGE 4 OF 30 PAGES

- 5. DEPARTMENT OF HEALTH AND HU~·IAN SERVICES FOOD AND DRUG ADMINISTRATION DISTRICT ADDRESS AND PHONE NUMBER , DATE(S) OF INSPECTION 250 Marquette Avenue, Suite 600 11 /29/2 010 - 01/07 / 2011* FEI NUMBER Minnea poli s, MN 55401 (612) 334-4100 Fax: (61 2 ) 334-4134 2128 643 Industry Information: www.fda . gov/oc/industry NAME AND TITLE OF INDIVIDUAL TO WHOfA REPORT ISSUED TO: Eric C . Haert l e, Chief Operating Officer FIRM NAME STREET ADDRESS H & P Industries, Inc. 70 0 W North Shore Dr CITY, STATE, ZIP CODE, COUNTRY TYPE ESTABLISHMENT INSPECTED Har tland, WI 53029-8358 OTC Drug and Dev ice Manufac t urer with missing or broken pull tabs. During the complaint investigation,a -etain tubes from lot OFI 43, product 10 8917, were examined and one of the pull tabs had fallen off. The complaints were closed as a "limited defect". • Incoming lubricating jelly tubes received from (b) ( 4) on 6/9/ 10, part number 10 8917TB had the address but were still accepted and used under deviation H061 0.004 ' has not received an onsite audit per the procedure "Supplier Qualification and Management System" #SOP-QA-0 I 0-0 l effective I 0/2811 0. OTC Drug Products Quali S stem OBSERVATION 7 The respons ibilities and procedures applicable to the quality control unit are not fully followed . a) The Quality Assurance Unit authorities most responsible for overseeing daily operations at this facility did not ensure that the responsibilities of the Quality Control Unit and Quality Assurance Laboratory were enforced for rejection of product that contained contamination. Quarterly dose samples of lot OL445 of sterile alcohol prep pads were found to be contaminated with organisms and were released for shipment after confmn ation of the results. Responsible officials did not follow their own procedure "Responsibilities of the Quality Department" #0 1-050 effective 9113/05 in that the product was not rejected. b) The Quality Assurance Unit did not follow their procedure "Quality Assurance lnvestig~A-004 -00 effective 9115110 in that INV- 10-003 initiated 12/0l/IO regarding the sterile alcohol prep pads with. . , . . .contamination was not extended to other sim ilar products, similiar investigations (CAP A- I 0-007), raw materials, customer complaints, and equipment used to manufacture alcohol prep pads. c) As of December l, 2010 the Quality Control Unit failed to initiate Qi@M investjation of out of specification results as per SOP-LAB-00 1-00, "Out of Specification lnvestigations( effective I 0/01110 for rL41QWChildren's Multi Symptom Very Berry, lot OK227B. Confirmatory OOS assay results fortfitEij j were obtained for the bulk release on 10/ 18/ 10. A result o (b) (4) was obtained (specification M Dt11 %). @miM investigation shou ld have been initiated by EMPLOYEE(S) SIGNATURE DATE ISSUED Marie A. Fadden , Consumer Safety Of ficer~ SEE REVERSE J oel D. Hustedt , Inves t iga tor DIJ/1 Sandra A. Hughes, Investigator ")J!l 01 / 07 / 2011 OF THIS PAGE Justin A. Boyd , Investi gator ~ FORM FDA 483 (09/08) PIE>10US EDITION OOSOL!Ore INSPECTIONAL OBSERVATIONS ~GE_s OF 30 PAGES

- 6. DEPARTMENT OF HEALTH AND HUMAN SERVICES FOOD AND DRUG ADMINISTRATION DISTRICT ADDRESS AND PHONE NUMBER DATE(S)-OF INSPECTION 250 Marquette Avenue, Suite 600 11/29/ 2010 - 01/07/2011* FEINUMBER Minneapo li s , MN 554 0 1 (612) 334-4100 Fax: (612) 334-4134 2128643 Industry Information: www.fda.gov/ oc/industry NAME AND TITLE OF INDIVIDUAL TO WHOM REPORT ISSUED TO: Eric C. Haertle, Chief Operating Officer FIRM NAME STREET ADDRESS H & P Industries, Inc. 700 w North Shore Dr CITY, STATE . ZIP CODE., COUNTRY TYPE ESTABLISHMENT INSPECTED Hartland, WI 53029-8358 OTC Drug and Device Manufacturer November 18, 20 I0. d) The Quality Control Unit failed to perform their responsibilities as required in procedure WI-LAB-00 II, "Testing for Microbiological Contamination in Samples", dated 81!1110 in that water ports which tested above the microbial action limit < cfulmL) were not additionally sampled after re-cleaning andre-sanitizing to confirm the effectiveness of the re-cleaning. . I) On 4/2110 microbial OOS results were obtained in Water Dispensing Values (DIY)# Results ranging from obtained . Products including Blue Mouth RinsdtiJDI Towel were manufactured m . which used this port between 4/1-511 0. 2) On 5/6/10, microbial OOS results were obtained for DIY • A result ofDIDJcfu was obtained. Products including Yellow Mouthrinse were manufactured in Tank.hich used this port on 5/4110. 3) On 9/3/10, microbial OOS results were obtained in DIY • . A result of. cfu was obtained. Products including Glycerin Suppository were manufactured in Tank. which used this port on 9/3110. e) No destruction documents were provided for the rejected products listed below. Procedure WI-ADM-0006, "Form Instruction for Notice of Destruction", dated 3/23/09 states that Quality Management is responsible for logging and filing all Notices of Destruction: I) Rejected Lot 500327 Sinus Relief Nasal Spray. The Bill of Lading documents the shipment of this product from the NJ location to Wisconsin on November 6, 2009 and was subsequently rejected by NJ. However no destruction documentation was provided for this lot. 2) Cases ~r[IDIIJIA !cohol Prep w/Benzocaine, lot OG478, were designated for destruction on August 13, 2010. Destruction of this product was never documented and the product is no longer on hand. · 3) OOS-1 0-053 investigated OG !54B. The OOS investigation stated the batch was scrapped, but there is no documentation of the destruction and the analyst completing the investigation stated she did not have any supporting information when she wrote that the batch was scrapped. The batch is no longer on hand . OBSERVATION 8 Drug products failin g to meet established specifications are not rejected. a) Samples from lot OL445 of sterile alcohol prep pads were submitted for ~rterly dose audit. Triad was informed by their contract testing laboratory on 11/30/10 the sterility test failed because iiiJIIil of theQBI samples had growth. A QA investigation, INV -10-003 , was initiated on 12/ 1/ I 0, but no lots of sterile alcohol pads were placed on~of lot OL445 were shipped to customers on 12/2/10. Identification of the sterility isolates were confirmed as - on 12/3/lO.IJildditional cases of lot OL44 5 were shipped from 12/ 10/1 0- 12114/ 10. b) There was no Sterile A I Swabstick sterilization validation prior to 6/14/10 and product was accepted with a minimum n ,VAL-0085-PVRPT-002, was completed and approved on 6114/ 10 establishing the minimum These new specifications have not been updated with the contract sterilizer. Product that was under steri was accepted and released for di9'tribution. EMPLOYEE(S) SIGNATURE DATE ISSUED M arie A. Fadden, Consumer Sa fety Of f icer1ltl:Rf SEE REVERSE J oe l D. Hu s t edt , Inve s ti ga t or " * Sandra A. Hughes , Investi ga t o r '11 01 / 07 / 2 011 OF THIS PAGE Jus t in A. Bo yd , Inve st iga t or ~ FORM FDA 483 (09/08) PREVIOUS EDIT ION OBSOLETE INSPES::TIONAL OBSERVATIONS PA GE 6 OF JO PAGES

- 7. DEPARTM 11/29 /2 010 - 0 1 07 2011* FEI 2128643 H & P Industries Inc . CITY, STATE, Hartland, WI 53029-8358 c) There was pad validation prior to 3/12/ 10. Specifications were not updated with the contract sterilizer from until 6/1/10. No investigation or health hazard analysis was conducted for the product on the market that was made without a validation and with a sterilization dose that was determined to be too low during the validation. OBSERVATION 9 The quality control unit Facks the responsibility and authority to approve all drug products. Finished product is being released into · it ion" ** The procedure states com FRM-QA-007 prior to the release of a product. Examples include but are not limited to the following cases: Product Name OBSERVATION 10 Control procedures are not established which monitor the output and validate the performance of those manufacturing processes that may be responsible for causing variability in the characteristics of in-process material and the drug product. a) Products to be transferred from the New Jersey facility include oral liquids, powders, nasal sprays, and tablets. There was no strategic plan documenting the transfer of the manufacture of these products to this location. Originally the company anticipated the transfer of all production of these new products to be complete bylijlll The- validation studies for the oral products currently transferred from the New Jersey facility do not demonstrate a high degree of scientific evidence that the batching I compounding processes are capable of consistently delivering quality products. The following observations were made during review of the validation studies : 1) The oral products are made in bulk mixing tanks - . In addition, a number of portable tanks can be used for premixes which will then be transferred to one of the bulk mixing tanks. Each ofthe bulk mixing tanks and each of the portable tanks are different in their dimensions, capacities, type of mixer and mixjng speeds. No documentation is available at the firm to demonstrate that the tanks are operationally equivalent or that the specified mixing parameters listed in the Mari e A. Fadden , Consumer Safety OfficerJh1tO/ Joe l D. Hustedt , Inve st iga tor ~~ SEE REVERSE Sandra A. Hughes, Investigator ~'11 01 / 07 /2 011 OF THIS PAGE Justin A. Boyd , Investigator~ fORl1 FDA 483 PREVIOUS EDillON ODSOLETE TIONS PAGE 7 OF 30 PAGES

- 8. DEPARTMENT OF HEALTH AND HUMAN SERVICES FOOD AND DRUG AOMfNISTRAT!ON DISTRICT ADDRESS AND PHONE NUMBER DATE(S) OF INSPECTION 250 Marquette Avenue, Suite 600 11/29/2010 - 01/07/2011* FEI NUMBER Minneapolis, MN 55401 (612) 334-4100 Fax: (612) 334-4134 1 2128643 Industry Information : www.fda.gov/oc/industry NAME AND TITLE OF INDIVIDUAL TO WHOM REPORT ISSUED TO: Eric C. Hae rtle, Chief Operating Officer FIRM NAME STREET ADDRESS H & P Industries, Inc. 700 W North Shore Dr CITY, STATE. ZIP CODE, COUNTRY TYPE ESTABLISHMENT INSPECTED Hartland, WI 53029-8358 OTC Drug and Device Manufacturer validation batch records for each tank are equivalent. Some of the products involve the use of multiple tanks which, in the absence of a comparability study, introduces the potential for batch-to-batch variability as multiple combinations of tanks can be used. 2) For each of the validation studies, the initial validation batch record contains several handwritten annotations for process improvements which are then transcribed on the batch records for the subsequent validation batches. These process improvements are also isted in the val' · amount of annotations on the initial validation batch records and their nature, such as renders the initial run a research and development batch and demonstrates that the not well established at the outset of the validation study. In addition, many of the validation studies involve size from the batc~t the New facir . Examples of products in which the validation studies involved ~batch size at the Hartland facMOftiMde, f Sore Throat Liquid Spray-Cherry, Sore Throat Liquid Spray- Mixed Berry, and Children's Grape. 3) The oral products may be transferred from one of the main mixing tanks to a holding tank following batch release testing and prior to fmished pro~aging. No studies have been conducted to determine the duration that the oral products can remain in holding tanks~rior to finished product packaging time, can range from ours. In addition, the holding tanks do not have agitators in them. The firm's "Tote or Tank Activity Record" (Form No: WI-PM-0090) identifies the batches held in the holding tanks, but it does not demonstrate the duration for which the batches were held. 4) Amendment 01 , associated with VAL-0 120-MBF-002, fori•>UM Children's Multi-Symptom-Very Berry, was written to include tank . in the manufacture of this ct without re-validation of the hatching process. The original validation of this product was conducted in tanks ·ustification to not re-validate wa:s based on tank . being used in the valid Children's Cherry and Mixed Berry, which were both deemed successful. However, each of the has different compositions including different combinations of active ingredients. The Children's Multi-Symptom Very Berry product contains the active ingredients Guaifenesin, Dextromethorphan Hydrobromide, and Phenylephine HCl whereas the Children's Cherry product contains Guaifencsin and Dextromethorphan Hydrobromide and the Children's Mixed Berry product contains Guaifenesin and Phenylephrine HCI. 5) Multiple fmished product lots manufactured from the validation batches were released to inventory prior to formal documented approval of the validation reports. The products and associated finished product lot numbers for products released prior to approval of the validation report include: o Night Time Cold & Multi-Symptom Liquid - Warming Honey Lemon, lot OF227 o Sore Throat Liquid Spray- Menthol, lot 0Jll7 o Ml Children's - Mixed Berry, lots OJ 118, OJ 150, OJ 138 o Acetaminophen Oral Suspension Infants' Drops- Grape, lot 01289 o C hildren's Night Time Cough & Cold- Grape, lots OH 177, OH 175 o ldren's Multi-Symptom -Very Berry, lots OH 153, OH 159, OH 156 o ldren's Cherry, lots OH260, OH261, OH262 6) Finished product lots made from the validation batches were not always put on stability. The product and associated lot EMPLOYEE(S) SIGNATURE DATE ISSUED M rie A. Fadden, Consumer Safety Office tfn~ a SEE REVERSE J oe l D. Hu sted t, Investigator~ Sandra A. Hughe s , Investi ga to ~~1 01 / 07/ 2011 OF THIS PAGE Justin A. Boyd, Investigator ~ FORM FDA 483 (09/03) PREVlOUS EDITION OBSOLETE _ INSPECTIONAL OBSERVATIONS PAGE 8 OF JO PAGES

- 9. DEPARTMENT OF HEALTH AND HUMAN SERVICES FOOD AND DRUG ADMINISTRATION DISTRICT ADDRESS AND PHONE NUMBER DATE(S) OF INSPECTION 250 Marquette Avenue, Suite 600 11 / 29 / 2010 - 01/07 / 2 0 11* FEI NUMBER Minneapolis, MN 5 5 401 (6 12 ) 3 3 4 - 4 1 0 0 Fax : ( 6 12 ) 3 3 4 - 4 13 4 2128 643 Industry Information: www.fda . gov/oc/industry NAME AND TITLE OF INDIVIDUAL TO WHOM REPORT ISSUED - TO: Eric C. Haertle, Chief Operating Officer FIRM NAMEi STREET ADDRESS H & P Industries, Inc. 700 W North Shore Dr CITY. STATE. ZIP CODE. COUNTRY TYPE ESTABLISHMENT INSPECTED Ha rtland, WI 53029-8358 OTC Drug and Dev ice Manufac t urer numbers ren esenting validation batches that were not put on stability include: o [mtM Children's - Mixed Berry, lot OJ ISO o Night Time Cold Liquid- Cherry, lots OE229, OE223 o Night Time Cold & Multi-Symptom Liquid- Warming Honey Lemon, lot OG ISO o Sore Throat Liquid Spray- Cherry, lots 01143, 01144 7) The three process validation batches for Night Time Cold & Multi-Symptom Liquid- Warming Honey Lemon were manufactured on 06/26/20 I 0 (batch OF227B), 07/08/2010 (batch OG ISOB), and 10/28/2010 (batch OK90B). Two batches of this product were made prior to the first validation batch; OF227B. The first validation batch- OF227B- was then followed sequentially by the second validation batch- OG ISOB, but- batches were manufactured between this batch and the third validation batch; OK90B. Per the QA Manager, all of the lots of product manufactured prior to the first validation batch and between the second and third validation batches were released. 8) OOS Preliminary Investigation Report OOS-10-0S2, dated 11/ 11110, was written to address a failing result for deliverable 1 volume detennination for Night Time Cold & Multi-S id- Warm · Lemon lot OF 162. The root cause determination for this result was " The investigation report also demonstrated that. cases were reworked, cases were released, and were scrapped. Per the fmn's Validation Final Report, VAL-0 109-MBF-002, batch OF 162B was manufactured prior to th_c first validation batch. This batch was not accepted for the first validation run due to the failing result and was placed on hold pending approval of OOS IO-OS2. OOS-IO-OS2 was approved on 12/06/ 10. b) the P~v.-·~0 u• 0 validation on aging lines, used to package oral liquid products · including Time Cough and Cold Guaifenesin and Phenylephrine Oral Pediatric, rtQIQW Cold Syrup, and Sore Throat Spray Menthol Liquid, did not include critical elements of the process and the affect on the drug products · I) The use of a , these filters were not included in the packaging validation but have been used on subsequent batches of product. The use of the filters was not always documented in the subsequent batch records. No studies have been done to show that these filters are appropriate for use with these products. 2) The pre-filter and final filter are changed during packaging if the filters are clogged with product. The affect of the filter change on the packaging process was not part of the packaging validation. 3) The conveyor speed during the packaging validation was not recorded and was not deemed important to the process. A subsequent batch of product had a deviation due to conveyor speed problems i.e. DEY-l O-INT-063. 4) Oven temperature for the tamper evident seal around the neck of the bottle was not part of the packaging validation and was not deemed important to the process. EMPLOYEE($) SIGNATURE DATE ISSUED Marie A . Fadden, Con s ume r Safety Of f icer~~~ J o e l D. Hust e dt , I n vestigator CJOJ:f Jll.lfr SEE REVERSE Sandr a A. Hughes, I nve s tiga tor'i'>l 0 1 / 07 / 20 11 OF THIS PAGE Just i n A. Boyd, Inves t iga tor ~ FORM FDA 483 (09/08 PREVlOUS EDITION OBSOLETE INSPECTIONAL OBSERVATIONS PAGE 9 OF 30 PAGES I

- 10. DEPA NUMBER 250 Marquette Avenue, Suite 600 - 01/07 / 2011* Minneapolis, MN 55401 (612) 334-4100 Fax: (612) 334-4134 2128643 Eric C. Haert le, Chief Hartland, WI 53029-8358 OBSERVATION 11 Control procedures fail to include adequacy ofmixing to assure uniformity and homogeneity. (b)(4) prior to batch release sampling. This demonstrates that the hatching described in the batch record may not provide a homogenous product in the tank. Examples of products with th include Children's Night Time Cough & Cold Grape, Night Time Cold & Multi-Symptom Liquid-Warming Honey, Children's Grape and Sore 'Throat Spray Menthol and Cherry. 2) The!IDIIMin-process sample for Children's Mixed an in-process & bulk release results data sheet that, original sample was retested and the initial results were confirmed in addition le failing (b) (4) Batch 011188 was transferred from tank. to a holding tank and samples were collected from the holding tank. The samples taken from the holding tank met specifications and the batch was released. 3) Following validation of Acetaminophen Oral Suspension Infants Drops- Grape,VAL-0149-MBF-002, the firm manufactured batch OL238B. The batch record (Revision No.: D), specifies the inclusion of the following instructions at step 1111 "(b) (4 ) 1 (b)(4) "A similar step was included in the current master batch record (Revision No .: C) for the Acetaminophen Cherry product as well. This 1@111 • step, just prior to batch release testing, was not part of the validation study, demonstrating that the process was not well established during the validation study. This R•~tep is addressed in Deviation lnvesti ion F DEY -I 0- . The root cause for this deviation was documented as follows: validation batch record OK 1148. Mari e A. Fadden, Consumer Safety Offi cer~ SEE REVERSE J oel D. Huste d t , Investigator Sandra A. Hughes, I nvestigator :)): ;Pf 01 / 07/ 2011 OF THIS PAGE Just in A. Boyd, Investigator~~ FORM FDA 483 PREVIOUS EDITION OBSERVATIONS PAGEIO

- 11. DEPART - 01/07 / 2011* 2128 6 43 Hartland, WI 530 2 9-8358 OTC and Devi c e Manufacturer OBSERVATION 12 Investigations of an unexplained discrepancy and a failure of a batch or any of its components to meet any of its specifications did not extend to other batches of the same drug product and other drug products that may have been associated with the specific failure or discrepancy. a) Quarterly dose audits of the sterilization cycle for sterile alcohol pads tesdli11Qiofproduct that represents all of the manufactured sterile alcohol pads for that quarter. On 11/30110 Triad was infonned the fourth quarter dose audit failed the sterility test. No lots of sterile alcohol pads were placed on hold, sterile alcohol prep pads distributed 12/ Ill 0- 12/14/ I 0 totaled approximate!y[lO!Idcases. b) For the oral products line, including but not limited to children's (h ) ( 4 ) produced is tested for Finished Goods Releas~s the composite sample. The OOS determined ~ can occur in a Jprior to packaging. Although the out of specifications span from August to December of201 0 and cases could be masked due to the comp~ investigation has been , nitiated into whether current product i on the market could potentially contain ~ c) Since the previous inspection in May 20 I 0, several OTC batches involving various products failed during annual stability studies. No investigation was documented detennining the affect of these failures to product currently on the market. d) Batches are partially rejected when an OOS is found . Investigations do not extend to other packing configurations that were packaged from the same bulk batch or to other batches of the same product. I) Batch OJ1 63 B of Bisacodyl Suppositories was used to fill- cases of 33- 10 I M ri e A. Fa dden, Con s umer Safety O ff i cer~ a Joe l D. Husted t, I nvestigator J}'Pit SEE REVERSE Sa ndra A . Hughes , I nve stigato~111 01 / 07/ 2 0 11 OF THIS PAGE Justin A . Boyd , Investigato r tfU FORJI<I FDA 483 PREVIOUS EDITION OBSOLElE INSPECTIONAL ORSER VAT

- 12. DEPARTMENT OF HEALTH AND HUMAN SERVICES FOOD AND DRUG ADMINISTRATION DISTRICT ADDRESS AND PHONE NUMBER DATE(S) OF INSPECTION 250 Marquette Avenue, Suite 600 11/29/2010 - 01/07/2011* FEI NUMBER Minneapolis, MN 554 01 (612) 334-4100 Fax: (612) 334-4134 2128643 Industry Information: www.fda . gov/oc/industry NAME AND TITLE OF INDIVIDUAL TO WHOM REPORT ISSUED TO: Eric C. Haertle, Chief Operating Officer FIRM NAME STREET ADDRESS H & P Industries, Inc. 700 W North Shore Dr CITY. STATE, ZIP CODE, COUNTRY TYPE ESTABLISHMENT INSPECTED Hartland, WI 53029-8358 I OTC Drug and Device Manufacturer cases of 33-10 16-· 33-1016. failed on the initial . A recheck sample was found to be within specification and the initial OOS was attributed The product was released. 33-1016f l awas found to be out of specification with a- assay and an investigation confirmed the result, however this investigation did not extend to the other portions of the same batch. From 33-1016-UBI-cases were destroyed and . cases that were inadvertently released were recalled. 2) Batch OK136 of Hemrrohidal Cooling w is used to fill . cases of 33-50048• • cases of 33-50048. - cases of 33-50046- - ,- ases of 33-50036 36-· . ,ample was taken from each product number, 33-50036. . failed on the initial test . A recheck sample was found to be within specification and the initial OOS was attributed to Product #33-50036-IDICialso failed (b) (4) assay and an investigation confmned the result. However, the investigation into the failing assay was discontinued because 33-50036-lllllwas packaged into the wrong tubes and the . cases were destroyed. All other cases made with batch OK136B were released. 3) Batch OG478B was used to fili i [liJIUWcase were tested with case cases fail . samples were then collectyd of case . , which also failed were scrapped and the remaining cases were released. Pad with Benzocaine, lot #OG478. Samples of the~ VIII being in specification. Additional and case M, which passed. Cases # OBSERVATION 13 Individuals responsible for supervising the processing and holding of a drug product lack the education to perform their assigned functions in such a manner as to assure the drug product has the safety, identity, strength, quality and purity that it purports or is represented to possess. Specifically, the individual responsible for providing training to the Microbiological Laboratory personnel is a Chemist with limited back()'round in Microbiolo()' OBSERVATION 14 Employees engaged in the processing and holding of a drug product lack the education required to perform their assigned functions . a) Employees performing the Microbiological testing of finished products and process water used to manufacture products and clean equipment, do not have an education in Microbiology. b) There is no one currently employed that has the education in the eng~ment for the production of pharmaceutical products i.e. alcohol swabstick production lines have~ after the product contact area, non-cleanable product contact surfaces on numerous pieces of equipment, lack of a preventative maintenance schedule for the compressed air system, lack of routine preventative maintenance of thetmiQ8in the Deionized Water system . EMPLOYEE($) SIGNATURE DATE ISSUED Marie A. Fa dde n, Consume r Safety Office~~ Joe l D. Hus t e dt, Investigator ~~ f'~Y I SEE REVERSE Sandra A. Hughes, Investigate~ • OF THIS PAGE Just i n A . Boyd , Investigator ~-~ FORM: FDA 483 (09/08) PREVIOUS EDITION OBSOLETE INSPECTIONAL OBSERVATIONS PAGE 12 OF 30 PAGES

- 13. DEPARTMENT OF HEALTH AND HUMAN SERVICES FOOD AND DRUG ADMINlSTRATION DISTRICT ADDRESS AND PHONE NUMBER DATE(S) OF INSPECTION 250 Marquette Avenue, Suite 600 h1/2~/20l0 - 01/07 / 20 11* FEI NUMBER Minneapolis, MN 55401 ( 6 12 ) 3 3 4 - 4 1 0 0 Fax : ( 612 ) 3 3 4 - 4 13 4 2128643 Industry Information: www.fda.gov/oc/industry NAME AND TITLE OF INDIVIDUAL TO WHOM REPORT ISSUED TO~ Eric C. Haertle, Chief Operating Officer FIRM NAME STREET ADDRESS H & P Industries, Inc. 700 W North Shore Dr CITY, STATE. ZIP CODE, COUNTRY TYPE ESTABLISHMENT INSPECTED Hartland, WI 53029-8358 OTC Drug and Device Manufacturer OBSERVATION 15 Employees are not given training in the particular operations they perform as part of their function , current good manufacturing practices, and written procedures required by current good manufacturing practice regulations. Specifically: a) Temporary employees are given cGMP training by the temporary agency that employs them, they do not receive any additional training at this company such as job specific training. In addition, cGMP training is not provided on a routine basis. For example: I) Operator- a temporary employee, received training from the temporary agency on 7/28/09 and started at this company on 7/29/09 .. Training since that time has included line clearance, raw data integrity and 10-up monthly maintenance. 2) Temporary employee . eceived training from the temporary agency on 8/4/08 and started at this company on 8/5/08, he hasn't received cGMP training since then . 3) Temporary employee- received training from the temporary agency on 11/ 13/09 and started at this company on 9/14/09, he hasn't received cGMP training since then. b) On 12/2/l 0 an employee was observed to of the master batch formula and mixing instruction for batch OM 1008. This step involved a of the batch. The employee completed the check, but there was not a second employee to verify the step. The operator explained the second employee that verifies this step in the b) (4) was busy. The operator would tell the second employee the check had been completed and the second operator would sign the "verified by" place in the record. c) The analysts performing the microbial out of specification investigation had never been trained on the procedure SOP LAB-002-00 00 "Microbiological Out of Specification (OOS) Investigations" effective 10/28/10. OBSERVATION 16 The number of qualified personnel is inadequate to perform and supervise the manufacture, processing, packing, and holding of each drug product. a) According to the QA individual responsible for following up on complaints, she does not have enough time to adequately investigate every complaint received. As of 12/29/J 0 this employee was terminated, a1 complaints received after that date are not being investigated. b) There areiiiPeople in the Quality Assurance department that are responsible for Quality Assurance for the entire company. With the short staff not all of the CAP A's are investir ted in a timely manner for example: ~ I) CAPA H-10-002, Failed - I was opened 2/2/10 to address oos......_ EMPLOYEE($) SlGNATURE DATE ISSUED Marie A. Fadden, Consumer Safety Off i cer~~ SEE REVERSE Joe l D. Hustedt, Investi gator ~~~ Sandra A. Hughes, Investigator~~ 01 / 07 / 2011 OF THIS PAGE Justin A. Boyd, Investigator FORM FDA 483 (09/08) PREVIOUS EDITION OBSOLETE INSPECTlONAL. OBSERVATIONS PAGE 13 OF 30 PAGES

- 14. DEPARTMENT OF HEALTH AND HUMAN SERVICES FOOD AND DRUG ADM!NISTRAT!ON DISTRICT ADDRESS AND PHONE NUMBER I DATE(S) OF INSPECTION 250 Marquette Avenue, Suite 600 11/29 /20 10 - 01/07/2011* FEINUMBER Minneapolis, MN 55401 (612) 334-4100 Fax: (612) 334-4134 2128643 Industry Information: www.fda . gov/oc/industry NAME AND TinE OF INDIVIDUAL TO WHOM REPORT ISSUED TO: Eric C. Haertle, Chief Operating Officer FIRM NAME STREET ADDRESS H & P Industries, Inc. 700 w North Shore Dr CITY. STATE. ZIP CODE. COUNTRY TYPE ESTABLISHMENT INSPECTED Hartland, WI 53029-8358 · OTC Drug and Device Manufacturer and has yet to be completed. 2) CAPA H-10-001 opened Jan 22,2010, has yet to address (b) (4) products. 3) CAPA H-1 0-005 opened 2/23/ l 0, has yet to address (b) (4) c) According to the Laboratory Manager, they do not have the staff to adequately investigate OOS test results, refer to observation #27 for a list of OOS investigations that were not timely. In addition, the Quality Control Manager stated they need . eople to conduct all ofthe testing (including transferred products), at the start ofthis inspection there were . laboratory staff members. d) At the start of this inspection there was one indvidual responsible for reviewing all batch records and lo. history packages t generated. This company generally produces over - batch records and lot history records in a month. OBSERVATION 17 Written procedures are not followed for evaluations done at least annually and including provisions for a review of complaints, recalls, returned or salvaged drug products, and investigations conducted for each drug product. Specifically, annual product reviews are not done for any of the OTC drug products manufactured at this facility in accordance with the rocedure "Annual Product Review" #Wl-QA-00 12 effective 9/23/09. OBSERVATION 18 Drug products are not quarantined before being released by the quality control unit. Specifically, during a tour of the warehouse on 12/10/10, we observed no less than. paUets of alcohol prep pads which were not tagged as 'HOLD", even though the firm agreed to put all such products on hold on 12/02110. Additionally, on 1/5111 investigators observed lube jelly and alcohol prep pads not on "HOLD"- Laborato Control S stem OBSERVATION 19 Each batch of drug product purporting to be sterile is not laboratory tested to determine conformance to such requirements. Specifically, there is no fmished product sterility testing or laboratory ~~~~~llllll···lt ·esting for sterile alcohol prep pads or - t sterile alcohol swabsticks. EMPLOYEE(S) SIGNATURE DATE ISSUED M ie A. Fadden, Consume r Safety Offi cer~ ar SEE REVERSE Joe l D. Hus tedt, Investigator /~l Sandra A. Hughes, Investigator~- 01 / 07 /2 011 OF THIS PAGE Justin A. Boyd, Investigator ~ FORM FDA 483 (09/08) PREVIOUS EDITION OBSOLETE INSPECTIONAL OBSERVATIONS PAGE 14 OF 30 PAGES

- 15. DEPARTMENT OF HEALTH AND HUMAN SERVICES FOOD AND DRUG ADMfN!STRAT!ON DISTRICT ADORESS AND PHONE NUMBER DATE(S) OF INSPECTION 250 Marquette Avenue, Suite 600 11/29/2010 - 01/07/2011* FEI NUMBER Minneapolis, MN 55401 (612) 334-4100 FaX: (612) 334-4134 2128643 Industry Information: www.fda.gov/oc/industry NAME AND TITlE OF IND:VIDUAL TO WHOM REPORT ISSUED TO: Eric C. Haertle, Chief Operating Officer FIRM NAME STREET ADDRESS H & P Industries, Inc. 700 W North Shore Dr CITY. STATE. ZIP CODE. COUNTRY TYPE ESTABLISHMENT INSPECTED Hartland, WI 53029-8358 OTC Drug and Devi ce Manufacturer OBSERVATION 20 Each batch of drug product required to be free of objectionable microorganisms is not tested through appropriate laboratory testing. There is no microbiological testing of the non-sterile alcohol prep pads and non-sterile swabsticks. OBSERVATION 21 Deviations from written specifications and sampling plans are not justified. sampling plan for Night Time Cold Liquid -Cherry was c to sample, consisting of of a packaging run. Testing consists of assay tests to determ change was reflected in all the oral liquid products transferred from the New Jersey location to this facility. b) Lot 0122 of Triad Antiseptic Hand Gel failed the fmished product assay for (b) ( 4) Investigation OOS-Wl0-003 was conducted, the failing results were confirmed, and the investigation concluded the specification was not appropriate. The product specifications were changed and the product was released. No deviation was written. c) Lot OD203B of Obstetricial Towelette Solution used Benzalkonium Chloride that was specifications of - and did not meet ingredient % for the active ingredient. Adjustments were made to the master formula to account for using -/ non-conforming ingredient. No deviation was written for using a non-conforming ingredient or adjusting the master formula. o d) Lot #OK274 of l l l sisacodyl Suppositories initially failed the Microbiological of Ml . actual result (b) (4 ) , the result was changed th no investigation or justification. EMPLOYEE(S) SIGNATURE DATE ISSUED M ari e A. Fadde n, Co n s ume r Safety O f fice ~ J oel D. Hust e dt , I nvestigator c?!JIIf SEE REVERSE Sandra A. Hughes, I nv e s tigat o r ?)n 01 / 07 / 2 011 OF THIS PAGE Justin A. Bo yd , Inv es t iga tor ~ FORJ1 FDA 483 (09/08) PI.EVIOUS EDITION OB SOL~"TE INSPECTIONAL OBSERVATIONS PAGE 15 OF J O PAGES

- 16. DEPARTMENT OF HEALTH AND HUMAN SERVICES FOOD AND DRUG ADMINISTRATION DISTRICT ADDRESS AND PHONE NUMBER DATE(S) OF INSPECTION 250 Marquette Avenue, Suite 600 11/29/2010 - 01/07/2011* FEI NUMBER Minneapolis, MN 55401 (612} 334-4100 Fax: (612} 334-4134 ! 2128643 Industry Information: www.fda.gov/oc/industry NAME AND T ITLE OF INDIVIDUAL TO WHOM REPORT ISSUED TO: Eric C. Haertle, Chief Operating Officer FIRM NAME STREET ADDRESS H & P Industries, Inc. 700 W North Shore Dr CllY, STATE, ZIP CODE. COUNTRY lYPE ESTABLISHMENT INSPECTED Hartland, WI 53029-8358 OTC Drug and Device Manufacturer OBSERVATION 22 Established sampling plans are not followed. a) Bioburden monitoring and quarterly dose audits (QDA) of the sterile alcohol pads and swabsticks are to be completed on a quarterly basis per SOP-LAB-005-00 "Performing Quarterly Dose Audits of Sterilized Products" effective 9/22110 which replaced SOP-Wl-QA-0006 effective 1/ll/07, the following audits did not follow these procedures: I) There was no quarterly dose audit conducted in quarter two of 20 I0 for sterile alcohol pads. 2) There was no quarterly dose audit conducted in quarter three of20 I 0 for sterile alcohol swabsticks. OBSERVATION 23 There is a failure to thoroughly review any unexplained discrepancy and the failure of a batch or any of its components to meet any of its specifications whether or not the batch has been already distributed. a) CAPA H-10-002, Failed(b)(4) was opened 2/2/ 10 to address OOS - results and has yet to be completed. There continues to be OOS B&esults. Procedure 01-013 revision B - "Corrective and Preventive Action Procedure which states in section 5.6 "** b) OOS-Wl0-0 16 investigated a microbial failure o (b) (4) The microbial OOS investigation was not conducted per SOP-LAB-002-00 "Microbiological Out of Specification (OOS) Investigations" effective 10/28110. OBSERVATION 24 Written records of investigations into unexplained discrepancies do not always include the conclusions and follow-up. a) Out of Specification investigations are not performed nor initiated in a timely manner. SOP-LAB-00 1-00 - " Out of Specification Investigations", effective date 10/01/10 states an investigation must be conducted at the time an OOS result is generated and that the investigation should be completed within . ays. The following investigations were not initiated nor com leted in a timely manner. Lot Date OOS Occurred OOS # Date OOS was initiated Date OOS was EMPLOYEE(S) SIGNATURE DATE ISSUED Marie A . Fa dde n , Con s umer Safety Office r ~ Joe l D. Hus t e dt, I nvestigator ()(!.~/;- SEE REVERSE OF THIS PAGE Sandra A. Hughes, Invest i gator Pl 01 / 07 /20 11 Justin A . Boyd, Investi gator ~ , FORM FDA 433 (09/08) PREVIOUS EDITION OBSOLETE INSPECTIONAL OBSERVATIONS PAGE 16 OF JO PAGES

- 17. DEPARTfviENT OF HEALTH A!'.'D HUMAN SERVICES FOOD AND DRUG ADMINISTRATION DISTRICT ADDRESS AND PHONE NUMBER DATE(S) OF INSPECTION 250 Marquette Avenue, Suite 600 11/2~ / 2010 - 01/07 / 2011* FEI NUMBER Minneapolis, MN 55401 (612) 334-4100 Fax : (612) 334-4134 2128643 Industry Information: www.fda.gov/oc/industry NAME AND TITLE OF INOIVIDUAL TO WHOM REPORT ISSUED TO: Eric C. Haertle, Chief Operating Officer FIRM NAME STREET ADDRESS H & P Industries, Inc. 700 W North Shore Dr CITY, STATE, ZIP CODE. COUNTRY TYPE ESTABLISHMENT INSPECTED Hartland, WI 53029-8358 OTC Drug and Dev ice Manufacturer 81123 11118/10 OOS-WI0-030 12/ 14/10 9K59 II/ 16/10 OOS-1 0-039 05/0511 0* 9HI69 11115/10 OOS-10-061 08111/10* ODI92 11/15110 l'lo OOS investigation ~as initiated. OD32 11115/10 No OOS investioation was initiated. OE434 11112110 OOS-WI0-031 12/ 14/10 9MI26 10/12/10 OOS-WI0-010 10/22/10 9KI64 I 0/12/10 OOS-W10-0W 10/22/10 7E169 09/02/ 10 OOS-10-066 09110/10 7E169 09/02110 OOS-10-042 05/ 17/10 81426 09/02/10 OOS-W 10-029 12/14/10 81178 09/02110 OOS-10-061 09110/10 7H43 08/09/10 OOS-10-068 I 09/ 10/10 7H05 08/09110 OOS-10-069 09/ 10/10 1 7F39 07/07110 OOS-W10-035 12115/10 OF187 10/12/ 10 OOS-W 10-008 10/22/10 7E10 05/25110 OOS-10-046 05/27/10 7F210 05/13/10 OOS-10-045 05/ 13/10 8G02 03/12/10 OOS-10-074 03/ 12110 ODI94B 4/26110 OOS-10-032 4/26110 OD203B 4/27110 OOS-10-033 4/27110 OD211B 4/29/10 OOS-10-036 4/29/10 8/18/ 10 OGI54B 7/8110 OOS-10-053 7/8110 1211311 0 OG478B 7/23/10 OOS-10-055 7/23/ 10 9HI69 8/11/10 OOS-10-061 8/ 11/ 10 *Added to a previously opened OOS investigation for issue. b) Deviation investigations are not performed in a timely manner. The following are examples of deviation investigations that were not timely: I) Deviation PI 006.002, initiated 12/05/02, was issued to change the test in of all alcohol re ad roducts fromtliJIQW (b) (4) tol l l l l · · · · · · · · · · · · · · for the batch. This result is for all lots for that day with the same batch number. Although not referenced, this deviation is still used for testing all prep pad products. This deviation has no end date. 2) Deviation DEY- · EMPLOYEE(S) SIGNATURE M arie A. Fa dde n , Con s ume r Safe t y Of ficer~~ SEE REVERSE J oel D. Hus t edt, Inves t iga tor ~~ Sandra A. Hughes, Investigator ~1 )' 01 / 07 / 2 0 11 OF THIS PAGE Jus tin A . Bo yd , Inves ti ga tor ~ FOR.-.J FDA 433 (09/08) PREVlOUS EDITION OBSOL £1"E INSPECTIONAL OBSERVATIONS PAGE 17 OF 30 PAGES

- 18. DEPARTMENT OF HEALTH AND HUMAN SERVICES FOOD ANQ DRUG ADMJNISTRATION DISTRICT ADDRESS AND PHONE NUMBER DATE(S) OF INSPECTION 250 Marquette Avenue, Suite 600 11/29 / 2010 - 01/07 / 2011* FEI NUMBER M nnea pol is, MN 554 01 i (612) 334-4100 Fax: (612) 334-4134 2128643 Industry Information: www.fda.gov/ oc/industry NAME AND TITLE OF INDIVIDUAL TO WHOM REPORT ISSUED TO: Eric C. Hae rtle, Chief Operating Offi c er FIRM NAME STREET ADDRESS H & P Industries, Inc. 700 W North Shore Dr CITY, STATE. ZIP CODE. COUNTRY TYPE ESTABLISHMENT INSPECTED Hartland, WI 53029-8358 OTC Drug and Device Manufactur er [(i]IIJM.. ***" OBSERVATION 25 Laboratory controls do not include the establishment of scientifically sound and appropriate test procedures designed to assure that components and drug products conform to appropriate standards of identity, strength, quality and purity. a) the method validation titled ''Validation of Microbiological Testing" #V AL-R-00 II dated 12/23/09 for the microbiological testing of all products and Deionized Water, used in production and cleaning, was not completed adequately in that the following were not determined: Precision, Specificity, and Linearity/Accuracy. In addition, the failure of the system suitability was not investigated and only a few of the many products tested were used in the method validation. b) method transfers were not completed on the following test methods prior to using them to release ora'! adult and children's drug products. In addition, there is no documentation to support that these methods, which are used for stability testing, are stability indicating. Document# Effective Date WI-LAB-0188 05119/ 10 WI-LAB-0 189 08/06/10 WI-LAB-0 190 0611 t/1 0 WI-LAB-0 192 08/07110 WI-LAB-0 194 07/29/10 WI-LAB-0 195 08/07/ lO WI-LAB-O f97 05/22/ 10 WI-LAB-0204 09/03/10 WI-LAB-0205 10/ 11/ 10 OBSERVATION 26 Testing and release of drug product for distribution do not include appropriate laboratory determination ofsatisfactory conformance to the final specifications prior to release. a) Procedure WI-LAB-00 18 - "Daily Verification of - Assay", Effective I0/2 3/06, describes the daily verification of the assay of solutions being packaged on th,UIII (prep pad) packaging lines. The following batch histories were not tested daily and yet still released by Quality: I) Lot OF501 , Product PL-1068)li1JQW Alcohol Prep Pads 20/100, dated 06/25110 was packaged on 6/25/ 10, 6/26/10, EMPLOYEE(S) SIGNATURE DATE ISSUED M ri e A. Fa dde n , Con s umer Safety Officer?f1~ a SEE REVERSE J oe l D. Hustedt , Inves ti gator~1( Sand ra A. Hughe s, Inve stigato r ~' ( 01 / 07 /2 0 11 OF THIS PAGE Just i n A. Boyd, I nves t i g ator FO RM FDA 483 (09/08) PREVIOUS EDilJill! OBSOLETE INSPECTIONAL OBSERVATIONS PAGE 18 QF JO PAGES

- 19. 11 /29/2 010 - 01/ 07/20 11* FEINUMBER 212 86 43 Hartland, WI 53029-8358 OTC D and Device Manufacturer 6/281!0. Ofthelllcases packaged, only case lijl@l were tested on 6/25/10. 2) Lot OE450, Product PL-1 068, MU@IMAlcohol Prep Pads 201!0{), dated 05/26110 was packaged on 5/26/ 10, 5/27110, 5/28110. Of the - ases case. was tested on 5/27110. 3) Lot OK440, Product 04-300 !coho! Prep Pad, medium 15/ 100, dated 10/14/ 10 was packaged on 10/14110, 10/ 15/10,and 10118/10. Of packaged,onlycas.wastestedfor on 10/14/IO, WCM ~as tested on 101141!0 and 10/18110. states " Suppos1tories, lot #OK274 was released without all testing on c) Numerous parameters listed on the finished Goods Inspection Check Sheet for oralljquid products are listed as "Not Applicable" although they pertain to the product being tested. The finn stated these attributes are inspected during in-process checks so they do not reinspect for them during finished product testing. This does not hold true for all potential defects listed. Parameters to be checked during in-process testing vs. fmished goods inspection are not defmed. OBSERVATION 27 The written stability testing program is not followed . Specifically, the finn has continued to miss stability time points since the previous inspection in May 20 I 0 in which the firm was cited for this observation. are not their own edure SOP-LAB-003-00 - "Stabil" Stu Pro " effective 10/28110 which states ** (b) (4) ** Solution Lot OBSERVATION 28 Results of stability testing are not used in detennining expiration dates. a) since the previous inspection in May 2010, several OTC batches involving various products failed during annual stability studies. Data obtained during stability testing is not used to determine if expiration dates need to be adjusted. Marie A. Fadde n, Consumer Safety Officer ~~ Joel D. Hus tedt, Investigator ~~ SEE REVERSE Sandra A. Hughes, Investi ga tor~ 01 / 07 / 20 11 OF THIS PAGE Justin A. Boyd, Investigator ~ FORM FDA48J OBSOLETE INSPECTIONAL OBSER PAGE 190f30

- 20. DEP - 01 07 /2011* 2128643 oc/indust Hartland, WI 53029-8358 Manufacturer b) The fum does not have a document which defines how products are categorized into 'families' even though product families determine which products are put on stability. OBSERVATION 29 Laboratory records do not include the lot number or other distinctive code of the sample. The Quality Control Unit failed to ensure that laboratory records, containing environmental monitoring and water testing raw data results, are traceable in that these documents do not contain a sample identification number. The following are examples of · laboratory records: a) Glycerin suppository room swabbing microbial results for 2/ 10 and 8/10 b) Stick room swabbing microbial results for 5/10, 8/10, and ll/10 c) r Dispensing Valves microbial testing results for 4110, S/ 10, 6/10, and 9/ 10 OBSERVATION 30 Procedures designed to prevent microbiological contamination of drug products purporting to be sterile do not include adequate validation of the sterilization process. Speciftcally, the validation for sterile alcohol pads only collected samples for bioburden determination from one production line. There are uction lines for alcohol Additionally, the recovered bioburden was not identified. Marie A. Fadde n , Consumer Sa f et y Officer~ Joel D. Hustedt, Investiga tor #~ SEE REVERSE Sandra A. Hughes, Investiga tor ~' 01 /07 /2 011 OF THIS PAGE Just in A. Boyd, Investigator FORM FDA 483 PREVIOUS EDITION OB SOLETE INSPECTIONAL OBSERVATIONS PAGE 20 PAGES

- 21. DEPARTMENT OF HEALTH AND HUMAN SERVICES FOOD AND DRUG ADM!NISTRATION DISTRICT ADDRESS AND PHONE NUMBER OATE(S) OF INSPECTION 250 Marquette Avenue, Suite 600 1_1/29/20 1 0 - 01/07 / 20 11 * FEINUMBER Minneapolis, MN 55401 (612) 334-4100 Fax : (612) 334-4134 212864 3 Industry Information: www.fda.gov/ oc/industry NAME AND TITLE OF INDIVIDUAL TO WHOM REPORT ISSUED TO: Eric C. Hae rtle , Chief Operating Officer FIRM NAME STREET ADDRESS H & P Industries, Inc . 700 W North Shore Dr CITY, STATE. ZIP CODE. COUNTRY TYPE ESTABLISHMENT INSPECTED Hartland, WI 53029-8358 OTC Drug and Device Manufacturer OBSERVATION 31 Deviations from written production and process control procedures are not recorded and justified. records and not documented by production employees. b) A QC Inspec of alcohol prep pads with benzocaine but it is not documented or described in production paperwork. c) numerous deviations have been documented approving the release of product or the use of inaccurate labeling without adequate justification including: 1) ~edium Sterile Alcohol Prep Pad Foil, the last 4 rolls of foil printed with the old TRIAD address (REV A), lthouo-h TRIAD moved to the current location in 2008 and REV B has been available since August 2009. (DEV -10- INT-053) )rli11QMouaifenesin and Dextromethorphan Cough Pediatric, Cherry, Lot OK109 was given an expiration date of October 012, and not September 2012. Product was released. (DEV-1 0- INT-036) ) Sterile Lubricating Jelly, Lot OG 192 was incorrectly coded with Lot OG 190. Product was released. (H09 10.009) ) Triadine PVP Scrub, 16 oz., Lot OHI3,~ases were produced with the product label containing LOT 08/ 13 EXP OH13 ·nstead of LOT OH13 EXP 08113. Product was released. (H0810.010 OBSERVATION 32 The master production and control records for each batch size of drug product are not prepared, dated, and signed by one person with a full handwritten signature and independently checked, dated, and signed by a second person. Specifically, the electronic batch record files for every product manufactured at this facility are kept on a shared network drive that is accessible to at leas. people. The Label Clerk responsible for issuing batch records demonstrated her ability to change any part of the batch record prior to issuance (including in process and fmished product specifications), these fields can be changed by anyone with access to the shared drive. In addition, the Label Clerk said she routinely changes the batch size based upon the production schedule to ensure that enough product is manufactured to meet demand. Batch records generated for production are not checked against the master batch record for accuracy. Master batch records are not signed. EMPLOYEE(S) SIGNATURE DATE ISSUED M r ie A. Fa dde n , Consumer Safe t y O ffi cer~ a SEE REVERSE J oel D. Hus t ed t , Investi gato~~ Sandra A. Hughes, I nvestigato r -~ l 01 / 071 2 011 I OF THIS PAGE Jus tin A . Boyd, Inve s tigato r ~ FORM F DA 483 (09/08) PRE'lOUS EDITION OBSOLETE INSPECTIONAL bBSERVATIONS PAGE 2 1 OF 30 PAGES I

- 22. DEPARTMENT OF HEALTH AND HUMAN SERVICES FOOD AND DRUG ADMfNISTRATION _ DISTRICT ADDRESS AND PHONE NUMBER DATE(S) OF INSPECTION 250 Marquette Avenue, Suite 600 11/29/2010 - 01/07 /20 11* FEINUMBER Minneapolis, MN 55401 ( 612 ) 3 3 4 - 4 1 0 0 Fax : ( 612 ) 3 3 4 - 4 13 4 2128643 Indu s try Info rmatio n: www.fda . gov/oc/industry NAME AND T ITLE OF INDIVIDUAL TO WHOM REPORT ISSUED TO: Eric C. Haertl e, Chief Operating Office r FIRM NAME STREET ADDRESS H & P Industries, Inc . 700 W North Shore Dr CITY. STATE, ZIP CODE . COUNTRY TYPE ESTABLISHMENT INSPECTED Hart l and, WI 53029 - 8358 OTC Drug and Device Manufacturer OBSERVATION 33 Written production and process control procedures are not documented at the time of performance. Specifically: a) On November 29, 2010 the production of Adult Glycerin Suppository lot #OL268 was observed. The operators were observed weighing the bulk totes and placing them in the appropriate area. Review of the batch record revealed that the weights had not been recorded for the first 25 totes of suppositories. Further discussion with the operator revealed that only one of the three could read and write english, as a result he is the only operator that can record information on the batch record and was not able to keep up with production and recording the information. b) An interview with an operator on December 2, 20 I 0 revealed that the operator documented in the batch record that he had added the active ingredient Phenylephrine to a batch oftmiCJ.hildren's Multi-Symptom Very Berry, lot #OK227B, when in fact it had not been added . In addition, the batch record has the addition of the active ingredient to the batch documented as "verified" by a second individual. OBSERVATION 34 Examination and testing of samples is not done to assure that in-process materials confonn to specifications. a) QC inspectors perform the In-Process Inspection according to the procedure "In-Process Product Inspection - Prep Pad Products" #WI-QC-0008 effective 9/23/09, however they do not record the actual number or(miQiunits found per section 3.2.2.1, for example: l) Triad Sterile Alcohol Pads, lot #OK423 , OM435, and OM422 - recorded "yes" rather then the number of!liJIQI.mits 2) QI@IMnon-sterile Alcohol Pads, lot #OK440 - did not record the number, a note states ' (b ) (4) I ***" c) The procedure "(b) (4) Test" #Wl-LAB-0042 effective 2/1 6/l 0 is not followed in that: l) according to the QC Supervisor, section 3. 1.1.4 is never done 2) accord in to the the re is never used for the ducts, however in the scope it states 11** * (b)(4) 4) according to the QC Supervisor, this procedure is used t- 1 test all products that are packaged into tubes, however EMPLOYEE(S) SIGNATURE DATE 'iSSUED M arie A . Fad d e n , Con s umer Sa f ety Officer1n~ J oel D . Hustedt , I nve s t igator ~Ill; SEE REVERSE Sandra A. Hughe s , Investigato r ~)}' 01 / 07/ 2 011 OF THIS PAGE Jus t i n A . Boyd, Investigator ~ I FORM FDA 483 (09/08) PREVIOUS EDITION OBSOLETE INSPECTIONAL OBSERVATIONS PAGE 22 OF 30 PAGES

- 23. .. DEPARTMENT OF HEALTH AND HUMANSERVICES FOOD AND DRUG ADMlNISTRATION DISTRICT ADDRESS AND PHONE NUMBER DATE(S) DF INSPECTION 250 Marquette Avenue, Suite 600 11/29 / 2010 - 01/07/2011* FEI NUMBER Minneapolis, MN 55401 (612) 334 - 4100 Fax: (612) 334-4134 2128643 Industry Informat ion: ~MW . fda.gov/oc/industry NAME AND T ITLE OF INDIVID UAL TO VVHOM REPORT ISSUED TO: Eric c. Haertle, Chief Operating Officer FIRM NAME STREET ADDRESS H & P Industries, Inc. 700 W North Shore Dr CITY. STATE. ZIP CODE , COUNTRY TYPE ESTABLISHMENT • NSPECTED I Hartland, WI 53029 - 8358 OTC Drug and Device Manufac ture r there is no reference in the procedure to testing tubes. OBSERVATION 35 The batch records do not record the distinctive identification nwnber to identify major equipment to show the specific equipment used in the manufacture of a batch of a drug product. Specifically, tanks used for batching the oral products are not specifically identified at the steps in which they are used in the execution of the batch record. The only place specific tanks are identified is in the "Process Equipment Cleaning and Sanitization" section of the batch record which demonstrates the tanks were cleaned prior to use. OBSERVATION 36 Actual yield and percentages of theoretical yield are not detennined at the conclusion of each appropriate phase of manufacturing of the drug product. a) The calculation of yield page was not completed in the batch record for the production of the Lemon Glycerin Swab Solution, lot #OM04B, the batch was released for packaging by Ilion 12/2/10. I b) The batch record documenting the production of Swab-Forming Solution, lot #OM120B does not include a y ield calculation page, this batch was released for the manufacture of swabsticks by . on 12/8110. c) The yield calculation page was not completed in the batch record for the production of Hemorrhoidal Suppository with phenylephrine, lot #OL245B. Facilities and Equipment System OBSERVATION 37 Equipment used in the manufacture, processing, packing or holding of drug products is not of appropriate design to facilitate operations for its cleaning and maintenance. llltJRoom: Alcohol Sterile and non-sterile prep pads packaging lines ( I l l: a) plastic "zip ties" are used to fonn the cotton into a fold -these "zip ties" touch every prep pad and have surfaces that are not cleanable b) a rubber neoprene wheel that was observed to have debris build up on it touches every prep pad on that side of the equipment c) the bars on which the prep pad material passes under were observed to have debris build up on it EMPLOYEE(S) SIGNATURE DATE ISSUED SEE REVERSE J oel D. Hustedt, Invest igator Sandra A. Hughes, Invest igator~· ?.!?t Marie A . Fadden, Consume r Sa f ety Officer~ . 01 / 07 / 2 011 OF THIS PAGE Jus tin A. Boyd, Inv es tigator ~ FORM FDA 483 (09/08) PREVIOUS EDITION OBSOLETE INSPECTIONAL OBSERVATIONS PAGE ZJ Of 30 PAGES