The need for flame retardant materials in the workplace has increased rapidly in recent years with the increased use of plastics, which are combustible and therefore hazardous around industrial machinery.

From smartphone and tablet production in the electronics industry to new energy efficiency measures in construction, employees are increasingly finding themselves working with flammable materials.

It is unsurprising then that 2,600 fires were reported in UK industrial premises in 2012-2013, putting pressure on employers to protect their staff whilst working in these volatile conditions. But flame resistance is not the only concern. With growing opposition from environmental organisations to traditional brominated flame retardants, the need to be eco-friendly is becoming less of a choice and more an obligation.

What are the problems with Brominated Flame Retardants?

There have been numerous studies carried out into the health effects of brominated flame retardants (BFRs) on man and animals. One such study added a BFR (hexabromocyclododecane HBCD) to the food of Wistar rats causing accumulation in the liver, decreased bone mineral density, neurobehavioural problems and decreased weight of the testis in the males.

As a result of findings like this HBCD has been added to a list of substances targeted for global elimination under the Stockholm Convention on Persistent Organic Pollutants. These toxic substances are known to be highly persistent in the environment by accumulating in the food chain, which has now resulted in increased levels being found in human breast milk in the UK.

Alternative eco-friendly flame retardants

As a result of the toxic effects, regulations have tightened around the use of BFRs and the chemical industry has gone to great lengths to develop alternative eco-friendly flame retardants.

From initial research into phosphorous-based chemicals to nanomaterials, halogen-free flame retardants are rapidly increasing their market share. They do not accumulate in the food chain, have a low toxicity profile and will eventually mineralize in nature, posing no harm to the environment.

Phosphorus-based flame retardants

A variety of inorganic and organic compounds fall under this heading and can be reactive products, which are chemically bound into the polymer material, as well as additive products, which are mixed into the material. They can be used in a variety of applications including polyurethane foams, thermosets, standard and engineering plastics, coatings and textiles.

The fire resistant properties of phosphorus have seen it widely used in the production of eco-friendly flame retardant fabrics. The reactive products are used in polyester fibres and also to form coatings for textiles with a wash-resistant flame retardant finish.

Nano-clay flame retardants

The fire resistant properties of clay are well known from its historical use as a roof tile, dramatically improving fire safety in homes. As a completely natural material, it also provides few environmental problems as it is easily disposed of, making it a perfect candidate for an eco-friendly flame retardant.

Clay naturally forms platelets which can be exfoliated and dispersed to separate the individual nanoscale layers bringing out the full extent of its flame resistant properties. These exfoliated platelets can then be added to a material slowing the spread of fire through the item as well as decreasing the spread to nearby objects due to reduced dripping.

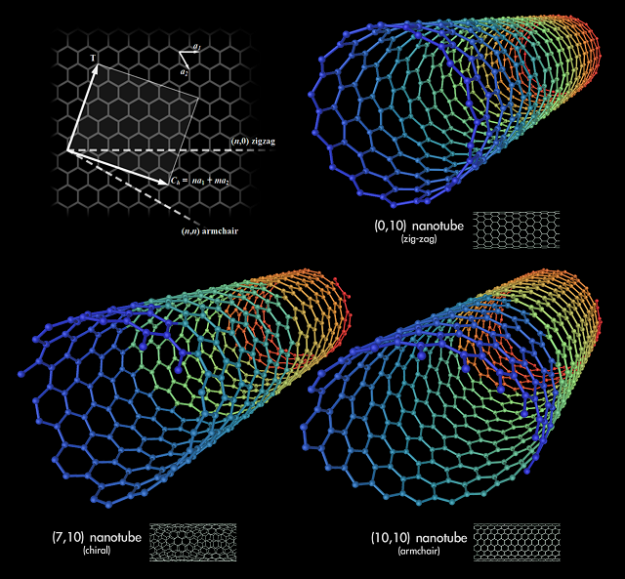

Carbon nanotube flame retardants

Carbon Nanotubes reduce the heat released by burning materials and can be used in conjunction with nanoclay filler to produce flame retardants which are more effective than either of the components when used alone.

Though highly effective, the cost of manufacturing carbon nanotubes is relatively high so, despite the low concentration needed, it is normally used in high value industries such as data centres.

Nano-intumescent Flame Retardants

Perhaps the biggest advancement in eco-friendly flame retardants has come with developments in nano-intumescent technology. Inspired by the technology to protect exposed steel beams in architecture, nano-intumescent flame retardants expand on contact to a flame to form tiny bubbles creating an insulating and protective barrier to the rest of the material. This prevents the material from igniting as opposed to alternatives which merely slow down the spread of fire. The nano technology is so small that the water-based polymers can soak into material such as cotton, coating every single fibre. This provides protection where toxicity is of great concern such as children’s pyjamas and car seats.

The height of protection

The future of eco-friendly flame retardant fabrics using nano-intumescent technology was put to the test in an experiment dealing only with completely renewable and environmentally benign electrolytes, cationic chitosan and anionic phytic acid. They were tested at different thicknesses and pH levels and found that all variations reduced the heat released, by a minimum of 50% and extinguished the flame in the vertical flame test.

The highest protection was found with the pH 4 solution, which is thought to be due to the high phosphorus content enhancing the intumescent behaviour of the coating. This experiment shows the first fully renewable intumescent assembly, marking a huge step forward in eco-friendly flame retardant fabrics. This should see a further decrease to the brominated flame retardants still being used.

For more information on our flame retardant protective clothing, check out the website or give a member of our team a call on 01635 527301 to discuss your needs.

Photo Credits:

Window panes – By MICHAEL GARCIA, CIV, DOD [Public domain], via Wikimedia Commons

Earth egg – by Mark Rain via Flickr under CC license 2.0

Carbon nanotube – By User Mstroeck on en.wikipedia [GFDL or CC-BY-SA-3.0], via Wikimedia Commons